Contact Us To Get The Hot Product Catalog

We are constantly exploring products tailored for the structural steel pipe market.

Here, you will find a unique product line designed specifically for the global market that pursues excellence and quality, aimed at meeting your various needs. Our goal is to become a leading global manufacturer of structural steel pipes, providing every customer with the high-quality products and services they expect.

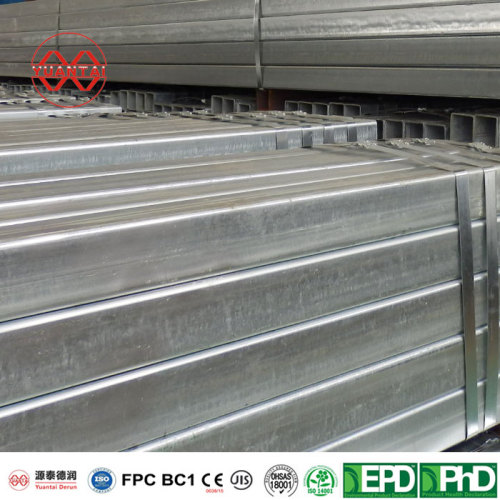

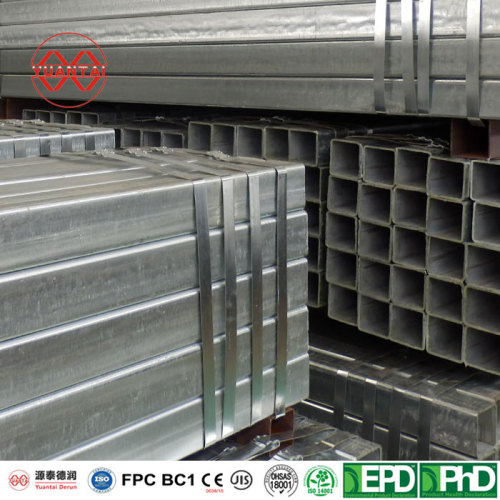

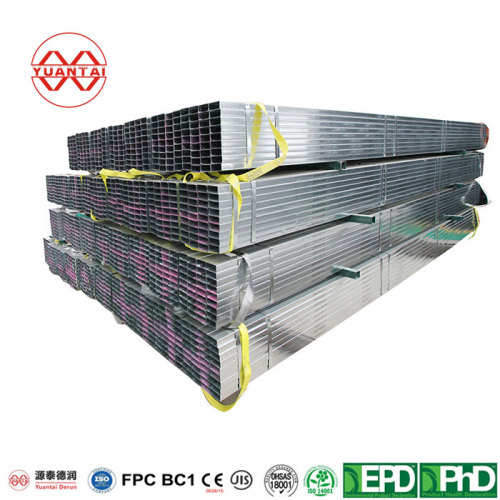

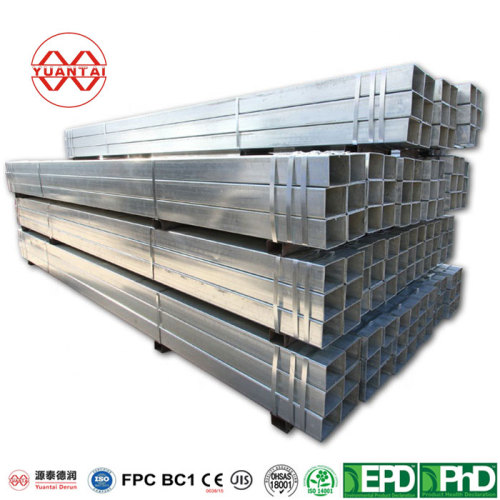

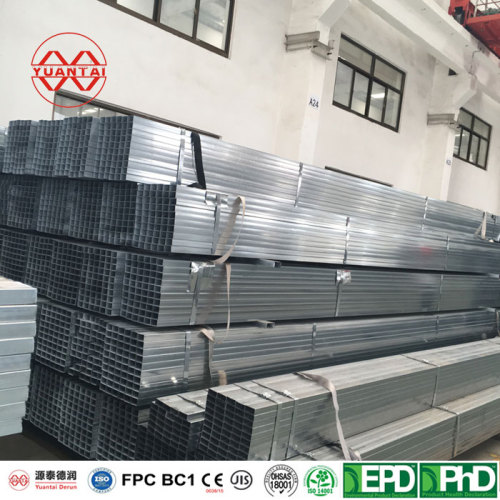

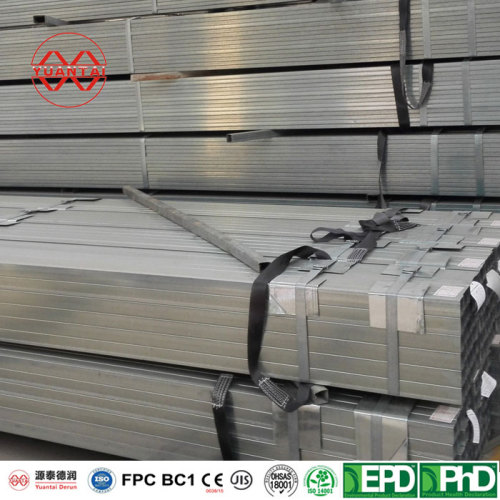

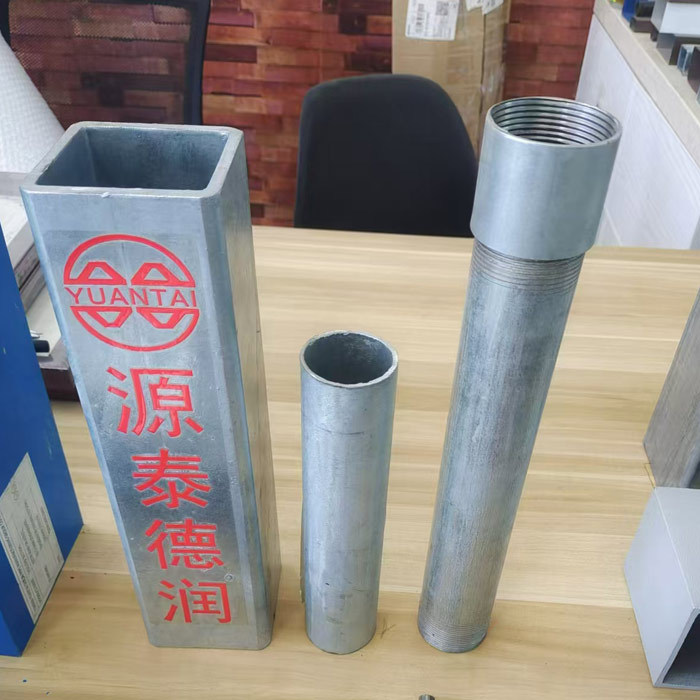

galvanized steel pipe

Galvanized steel pipe is coated with zinc to make it less likely to rust. This treatment prevents rust on steel pipes. Galvanized steel pipes are mainly divided into hot-dip and pre-galvanized. They have many uses, including construction, machinery, coal mining, chemical engineering, electricity, railway vehicles, the automotive industry, highways, bridges, and more. They are especially useful in fire protection, electricity, and highway construction because they resist corrosion and have good mechanical properties. Yuantai Derun is a large galvanized steel pipe factory in China. Contact Us Now!

Shape: round,square,rectangular,shaped

Surface: hot dip galvanizing or pre galvanizing

Wall Thickness(WT): 0.5-60mm or on demand customization

Length: 0.5-26M or on-demand cutting

Tolerance:±5% or According to customer standards

Common Specifications For Inventory: See daily stock chart for details

Inventory Quantity: See Packing Quantity for details

Outer Diameter: square10*10-1200*1200mm

rectangular 10*15-800*1200mm

round 10.3-3620mm

Type: ERW/LSAW/SSAW/Seamless

Grade: Gr.A/B/C,S235/275/355/420/460,A36,SS400,

Q195/235/355,STKR400/490,300W/350W

Delivery Time: 3-35 days

MOQ: 2-5 Tons

Payment Term: TT/LC

Brand: Yuantai Derun or OEM

Capacity: 1 million tons per year

Type Of Galvanized Steel Tube On Sale

At present, Yuantai Derun can produce two types of galvanized steel tubes, one is pre galvanized steel tube and the other is hot dipped galvanized steel tube(hdg steel pipe). Welcome everyone to inquire and place orders.

Hot Dipped Galvanized Steel Tube

Pre Galvanized Steel Tube

Complete Specifications For You

The galvanized steel pipe production line of Tianjin Yuantai Derun Pipe Manufacturing Group is equipped with 16 Hot-dip galvanization steel pipe production lines and 9 pre galvanized steel pipe production lines. The production bases are located in Tangshan and Tianjin. The dimensions of galvanized steel pipes that can be produced are as follows:

Outer diameter 10 * 10-1200 * 1200mm Wall thickness: 0.5-60mm Length 0.5-24M

Outer diameter 10 * 15-800 * 1200mm Wall thickness: 0.5-60mm Length 0.5-24M

Diameter 10.3-3000mm Wall thickness: 0.5-60mm Length 0.5-24M

Outer diameter 20 * 20-200 * 200mm Wall thickness 1.2-16mm Length 0.5-24M

Outer diameter 20 * 30-150 * 300mm Wall thickness: 1.2-16mm Length: 0.5-24M

Diameter 10.3-200mm Wall thickness: 0.5-16mm Length: 0.5-24M

No matter what size, thickness, or length you need, we can follow your needs for mass customization production.

Characteristics

(1) High wear resistance: Galvanised steel pipes are highly resistant to abrasion and are able to withstand a variety of mechanically abrasive environments.

(2) High strength: The strength of galvanized steel pipes is higher than that of other metal building materials, for example, the load-bearing strength of aluminum pipes is much lower than that of galvanized steel pipes.

(3) Strong corrosion resistance: Hot dip galvanised steel pipe and pre-galvanised steel pipe are higher in corrosion resistance than ordinary black carbon steel pipe, the galvanised layer can well protect the surface of carbon steel from corrosion in the external environment, the life of the pipe is also greatly extended.Galvanised steel pipes are the best choice when it comes to salt spray environments at the seaside, acidic environments and alkaline environments in the chemical and manufacturing industries.

Application

|

galvanized structural pipe

|

Used in the fields of building structures, bridges, road guardrails, etc., it is required to have a smooth surface and uniform galvanized layer.

|

|

galvanized pipe for hydraulic support

|

Used for oil and gas extraction and transportation pipelines, it has high corrosion resistance and pressure resistance.

|

|

galvanized pipe for gas

|

Pipelines used for transporting oil and natural gas require corrosion resistance, pressure resistance, and wear resistance.

|

|

large diameter galvanized pipe

|

Galvanized pipes with a diameter greater than 406mm are mainly used for pipeline systems or structural pile foundations for transporting liquids, gases, or solid particles.

|

Small and medium-sized galvanized pipes | Galvanized pipes with a diameter less than 406mm are commonly used in pipeline systems in construction, industrial, and municipal engineering. |

70 products found

ViewShowcase

Discover the excellence of our gp square pipe EN10210 hot rolled structural steel tube. We offer OEM, distributorship

Discover top-notch High-Quality ASTM A500 Pre Galvanized Hollow Square Pipes manufactured by China's leading supplier.

Yuantaiderun HFRHS-EN 10210-S355J0H-100x100x8mm: Superior Hot Galvanized Rectangular Tubes - Good Quality for Wholesalers.

Discover the Power of EN10219 S420MLH Hot Galvanized Square Pipes - The Leading Manufacturer and Trader in China.

Discover Excellence in Steel Pipes: Hot Galvanized Square Pipe ASTM A 500 B (or) S275 JR Square Hollow Sections.

Expand your business reach with Premium Pre-Galvanized Square Pipes: Offering OEM/ODM Solutions to Empower Global Brands.

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- Steel Pipe

- Steel Profile

- Steel Coil

- USE

- Structural steel pipe

- Fluid pipe

- Shape

- Square steel pipe

- Rectangular steel pipe

- Round steel pipe

- Shape tube

- Turface Treatment

- Black steel tube

- Pre galvanzied steel tube

- Hot dip galvanized steel tube

- Zinc aluminum magnesium coating steel tube

- Material

- Carbon steel pipe

- Alloy steel pipe

- Stainless steel pipe

- Standard

- EN10210

- EN10219

- ASTM A500

- ASTM A501

- ASTM A53

- ASTM A106

- ASTM A572

- ASTM A992

- JIS G3466

- AS/NZS 1163

- CSA G40.20

- CSA G40.21

- API 5L

- API 5CT

- Molding Process

- ERW steel pipe

- LSAW steel pipe

- Spiral welded steel pipe

- Seamless steel pipe

- Sales Attributes

- Sample list

- OEM

- ODM

- New arrival

- Basic style

- Star style

- Cross Section

- C channel

- Z channel

- U channel

- Round steel rod

- Rebar

- Angle steel

- H beam

- Raw material

- carbon steel profile

- Stainless steel profile

- Alloy steel profiles

- Surface Treatment

- Zinc aluminum magnesium steel coil

- GI steel coil

- PPGI coil

- Stainless steel coil

- Steel plate

- Steel strip

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content