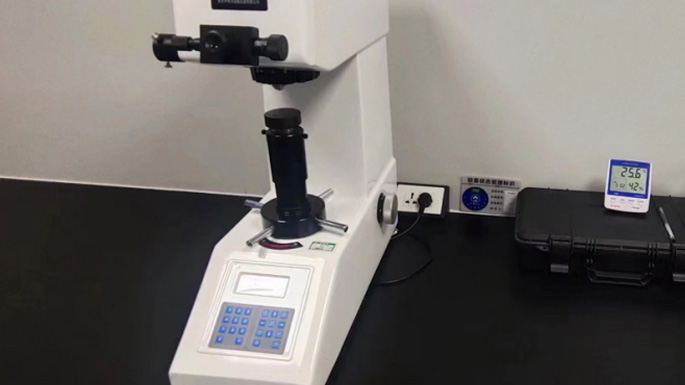

The role of metallographic analyzers in the detection of steel materials cannot be ignored. During their work in the metal material physics and chemistry laboratory, the main methods they use to test materials are as follows: in terms of physical properties, such as conductivity, magnetic conductivity, thermal conductivity, density, melting point, thermal expansion, and mechanical properties, we can use testing machines to conduct quantitative tests such as compressive strength and flexural strength, or chemical composition testing. In addition, a qualitative analysis of material composition can be carried out through a multi-element analyzer, and in addition, the microstructure of materials can be detected through optical microscope or Scanning electron microscope and other equipment.

Metallographic analysis plays a significant role in detecting materials, and it also plays a very important role. To establish a relationship between performance, we must thoroughly understand the metallographic organization space, which can be easily achieved through metallographic analysis. Some people may say that the data from metallographic analysis may not be so accurate. If you find the accuracy low, you can use a metallographic image analyzer to detect it. Of course, in general, we only need to use metal analysis directly. The metallographic image analyzer can detect and analyze various steel materials such as cast iron, ductile iron, stainless steel, heat-resistant steel, and so on.