Contact Us To Get The Hot Product Catalog

We are constantly exploring products tailored for the structural steel pipe market.

Here, you will find a unique product line designed specifically for the global market that pursues excellence and quality, aimed at meeting your various needs. Our goal is to become a leading global manufacturer of structural steel pipes, providing every customer with the high-quality products and services they expect.

LINE PIPE&OCTG

Pipeline

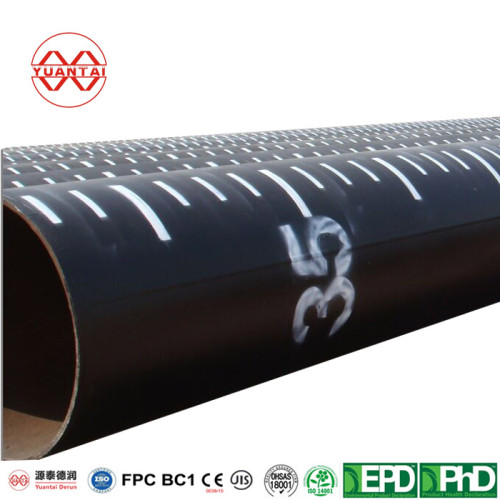

Pipeline: It refers to the transportation of oil, gas, or water extracted from the ground to oil and gas industrial enterprises through pipeline. Pipeline pipes include seamless and welded pipes, with flat ends, threaded ends, and socket ends; The connection methods include end welding, coupling connection, socket connection, etc.

Current Situation and Prospects of Deep Sea Oil and Gas Exploration

In recent years, 50% of the major oil and gas exploration discoveries globally have come from the ocean, mainly in deep water areas. Global deepwater oil and gas exploration is mainly concentrated in the Gulf of Mexico, Brazil on both sides of the South Atlantic, and the coastal areas of West Africa, which account for about 84% of the world's current deepwater oil and gas drilling activities; Among them, the Gulf of Mexico is the largest (accounting for 32%), followed by Brazil (accounting for 30%), and the third is West Africa. As of now, the total proven reserves of oil and gas in major deepwater areas in the world are 2.060 3 × 1010M3。 According to Douglas Westwood, a British company, 44% of the world's oil geological reserves in the future will come from deep water areas.

Over View Of Line Pipe

Pipeline specifications: 10.3×0.5-3000×60mm

Executive standards: GB/T9711.1/API SPEC 5L

Purpose:Used for gas, water, and oil transportation in the petroleum and natural gas industries

Pipeline material:Steel grades L245, L290, L360, L415, L480, GR. B, X42, X46, X56, X65, X70, X80, X100, etc

Pipeline Classification And Application

The pipelines used in offshore oil fields can be divided into: OCTG pipelines for subsea oil and gas wells, long-distance transmission pipelines, and internal connection pipelines for offshore oil and gas fields (including subsea gathering and transportation pipelines, risers, and working connection pipelines). OCTG is a seamless steel pipe used for oil and gas well drilling; The amount of pipes used for long-distance transportation pipelines accounts for approximately 40% of the total amount of submarine pipeline pipelines; The internal connecting pipes of offshore oil and gas fields refer to the gathering and transportation pipelines, injection medium pipelines, and connecting short pipes from each wellhead to the gathering point in the oil and gas field. The connection between the seabed and offshore facilities is a vertical pipe, which mainly uses seamless steel pipes. The steel grade and wall thickness of the vertical pipe are a series higher than those of the gathering and transportation pipeline.

Pipeline Characteristics:

Due to the influence of installation, laying, and service environment, deep-sea pipeline pipes have characteristics such as high strength, high toughness, weldability, corrosion resistance, and resistance to large deformation. They have higher requirements for dimensional accuracy, surface quality, measurement and inspection methods, and product traceability. Regarding the characteristics of high strength, high toughness, weldability, corrosion resistance, and large deformation resistance of deep-sea pipeline pipes, China began to develop and research high-performance subsea pipelines in 2005. Currently, Tianjin Yuantai Derun Steel Pipe Manufacturing Group has developed X65 and X70 marine steel. By controlling the production processes of steelmaking, rolling, and heat treatment, its strength, toughness, weldability, corrosion resistance, and large deformation resistance can all meet the requirements of deep-sea, And successfully used in the deep sea.

Technical Requirements For Deep Processing Of Deep-sea Pipeline Pipes And General Pipeline Pipes

Comparing the API Spec 5L-2012 Pipeline Steel Pipe Specification, DNV-OS-F101-2013 Subsea Pipeline System Specification from Det Norske Veritas, DEP 31.40.20.35-Gen Shell Pipeline Pipe Specification, GS EP PLR 201 Total Pipeline Specification, and customer requirements in deep-sea pipeline projects such as the South China Sea Liwan Project and the Brazil Petrobras deep-sea project, it was found that the deep processing requirements for deep-sea pipeline pipes are generally higher than those for general pipeline pipes, Mainly manifested in the following aspects.

(1) In terms of geometric dimensions, there are higher requirements for accuracy such as outer diameter, ovality, and wall thickness, while there are strict requirements for pipe end accuracy and length deviation. The comparison of geometric dimension accuracy requirements between ordinary pipeline pipes and deep-sea pipeline pipes is shown in Table 2. The required inner diameter deviation of steel pipes for some deep-sea pipeline projects is shown in Table 3.

Table 2:Allowable error range for ordinary pipeline pipes and deep-sea pipeline pipes

CASE(项目) |

Allowable range of deviation for ordinary pipeline pipes(普通管线管偏差允许范围) |

Allowable range of deviation for deep-sea pipeline pipes(深海管线管偏差允许范围) |

|||

D/mm(外径) |

Tube body (管体) |

D≤60.3,-0.8~+0.4; D>60.3,±0.0075D

|

±0.5或±0.0075D,Take the larger one(取较大者)

|

||

|

Pipe end(管端)

|

D≤168.3,-0.4~+1.6; D>168.3,±0.005D,But the maximum value is ±1.6 |

±0.5或±0.005D,Take the larger one(取较大者),but the maximum value is(但最大值为) ±1.6

|

|||

Ellipticity (椭圆度)/mm |

Tube body (管体) |

≤0.020D

|

D/t≤75,≤0.015D;

D/t>75,≤0.020D,but the maximum value is(但最大值为) 1.5 |

||

Pipe end(管端) | ≤0.015D | D/t≤75,≤0.010D; D/t>75,≤0.015D,but the maximum value is(但最大值为) 7.5 | |||

Local ellipticity(局部椭圆度)/mm | No requirements(无要求) | >0.005D,but ≤2.5 | |||

Curvature(弯曲度)/mm | ≤0.002L;Pipe end(管端)1 m≤4 | ≤0.002L;Pipe end(管端)1 m≤4 | |||

Wall Thickness(壁厚) t/mm | t≤4,-0.5~+0.6; 4<t<25,-0.125t~+0.150t; t≥25,-3.0~+3.7 or -0.1t~+0.1t,take the larger one(取较大值) | t<10,±0.125t; t≥10,±0.1t,the maximum value(最大值为) is±3; | |||

Length(长度)L/mm | There are 6 length requirements, each with a range and average length, determined by the order(有6个长度要求,每个都有范围及平均长度,由订单决定) | Meet the length and tolerance requirements specified in the order (满足订单指定的长度及公差要求) | |||

Weight(重量)/t | The difference between the actual mass and theoretical mass of each piece is -3.5% to+10%; For batches of over 18t, the total difference is -1.75% to+10%(每根实际质量与理论质量差- 3.5%~+ 10% ;18t以上的批量,总量差为-1.75%~+ 10%) | The difference between the actual mass and theoretical mass of each piece is -3.5% to+10%; For batches of over 18 tons, the total difference is -1.75% -+10%(每根实际质量与理论质量差- -3.5%~+10% ;18 t以上的批量,总量差为-1.75%-+10%) | |||

Perpendicularity of pipe end/(°)(管端垂直度) | 90,deviate(偏离)≤1 | 90,deviate(偏离)≤1 | |||

Groove (坡口) | Except as agreed, the angle tolerance for a groove angle of 30 * is 0 °~5 °, and the tolerance for the blunt edge of the groove is (1.6+0.8) mm(除协议外,坡口角度30*时的角度公差0°~5°,坡口钝边公差( 1 .6+0.8)mm) | Except as agreed, the angle tolerance for a groove angle of 30 * is 0 °~5 °, and the tolerance for the blunt edge of the groove is (1.6+0.8) mm(除协议外,坡口角度30*时的角度公差0°~5°,坡口钝边公差( 1 .6+0.8)mm) | |||

Note: The allowable deviation range for ordinary pipeline pipes (PSL2) is summarized according to API Spec 5L-2012, while the allowable deviation range for deep-sea pipeline pipes is summarized according to DNV-OSF101-2013.

Table 3: The required inner diameter deviation of steel pipes for some deep-sea pipeline projects

|

Pipeline project (管线管项目) |

Engineering Party (工程方) |

Inner diameter requirement (内径要求)/mm |

|

|

Egypt Deep Sea Pipeline Project(埃及深海管线项目) |

Saipem

|

OD≤310 ,take(取)±0.5或0.3% ID the larger one among them中的较大者; 0D>310,take(取)±1.6

|

|

|

Malaysia Deep Sea Pipeline Project(马来西亚深海管线项目) |

Sapura Acergy

|

OD≤323.9 ,take(取)±0.5或0.3% ID the larger one among them(中的较大者); 0D>323.9,take(取)±1.6 |

|

|

North Sea Deep Sea Project (北海深海项目) |

Subsea 7

|

OD≤273 ,take(取)±1; OD>273,take(取)±1.6

|

|

Chevron Indonesia Deep Sea Project(雪佛龙印尼深海项目) | Saipem | OD≤310 ,take(取)±0.5或0.3%OD the larger one among them中的较大者; 0D>310,take(取)±1.6 | |

Ghana Deepwater Project (加纳深水项目) | Technip | Nominal inner diameter(名义内径) ± 1.0 | |

Mozambique Deepwater Project (莫桑比克深水项目) | Technip | Nominal inner diameter(名义内径) ± 1.0 | |

Indonesia Deep Sea Project (印尼深海项目) | Saipem | ID±0.2 | |

Indonesia JKK Project (印尼JKK项目) | Technip | ID ± 1.6, pipe end wall thickness tolerance ± 1.0 | |

(2) The maximum test pressure for the hydrostatic test of deep-sea pipeline pipes needs to reach 200 MPa. The comparison of the hydrostatic test pressure requirements between ordinary pipeline pipes and deep-sea pipeline pipes is shown in Table 4.

Table 4 Comparison of hydrostatic test pressure requirements between ordinary pipeline pipes and deep-sea pipeline pipes

|

Ordinary pipeline pipes (普通管线管)

|

Deep-sea pipeline pipes(深海管线管)

|

||

|

D ≤ 141.3 mm or A, B steel grade: P=120t/D; 141.3 mm<D ≤ 219.1 mm, X42 steel grade and above: P=150/D; 219.1mm<D ≤ 508 mm, X42 steel grade and above: P-170/D. Stable voltage for no less than 5 seconds (D≤141.3 mm或A、B钢级: P=120t/D ; 141.3 mm<D≤219.1 mm , X42钢级以上: P=150/D ; 219.1mm<D≤508 mm , X42钢级以上:P-170/D。稳压不少于5s) |

P=2tmin×0.96Rmin/(D-tmin),Stable voltage for no less than 10 seconds

(稳压不少于10S) |

||

(3) The number of inspection projects has increased, and both the finished pipe body and pipe end require ultrasonic testing UT and wet magnetic particle testing ST, with a coverage rate of UT testing reaching 100%; After groove processing, fluorescent wet magnetic particle inspection shall be carried out on the pipe end and groove within 250mm; The requirements for the qualification of flaw detection personnel are higher. The comparison of flaw detection requirements between ordinary pipeline pipes and deep-sea pipeline pipes is shown in Table 5.

Table 5 Comparison of Flaw Detection Requirements between Ordinary Pipeline Pipes and Deep Sea Pipeline Pipes

|

Inspection content (探伤内容) |

Ordinary pipeline pipes(普通管线管)

|

Deep-sea pipeline pipes(深海管线管)

|

|

|

Defect detection (缺陷探伤) |

Pipe body(管体)

|

One or more combination of electromagnetic, magnetic particle, and ultrasonic testing methods. Verification of artificial injury: electromagnetic (eddy current) 3.2mm through-hole; Electromagnetic (magnetic leakage) and ultrasonic longitudinal L4 level (depth 12.5% t) grooves. Horizontal direction is not required during ultrasonic testing(电磁、磁粉、超声波中的一种或几种组合检测方式。校验人工伤:电磁(涡流)3.2mm通孔;电磁(漏磁)及超声波纵向L4级(深12.5%t)刻槽。超声波检测时横向不要求.)

|

Ultrasonic vertical and horizontal L2 level (deep 5% t), some projects require ultrasonic and magnetic particle testing(超声波纵横向L2级(深5%t) ,某些项目要求超声波+磁粉探伤) |

|

Pipe end(管端)

|

Manual ultrasonic or magnetic particle testing, with the same defect level as the pipe body (手动超声波或磁粉检测,缺陷等级与管体相同) |

Ultrasonic or magnetic particle testing of pipe end grooves, with the same defect level as the pipe body. Some items require ultrasonic and magnetic particle testing (超声波或管端坡口磁粉检测,缺陷等级与管体相同,某些项目要求超声波+磁粉探伤) |

|

|

Layered inspection (分层探伤) |

Pipe body(管体)

|

No requirements (无要求) |

Artificial defect 6 mmx35 mm, coverage rate 100% (人工缺陷6 mmx35 mm ,覆盖率100%) |

Pipe end(管端) | According to the protocol requirements, the detection area is 25mm, with artificial defects φ 6mm flat bottom hole (按协议要求进行,检测区域25 mm,人工缺陷φ6 mm平底孔) | Detection area 50mm, artificial defect 6mm flat bottom hole (检测区域50mm,人工缺陷6mm平底孔) | |

Thickness measurement (测厚) | No requirements (无要求) | Coverage rate 100% (覆盖率) | |

(4) The requirements for surface defects are also stricter, and there should be no cracks, cracks, or scratches. The depth of surface defects should not exceed 5% of the nominal wall thickness; The actual wall thickness after grinding shall not be less than the minimum wall thickness.

(5) Increase traceability management. In the production process of deep-sea pipeline pipes, it is necessary to collect more production and quality information, and achieve tracking of production information one by one, including water pressure, flaw detection, geometric dimensions (length, inner and outer diameter of pipe ends, wall thickness of pipe ends, etc.), size distribution, and other information. This requires each steel pipe to be marked with a different code from the time it enters the production line. The marking should be clear and not easily damaged, and hanging tags should not be used. It should be clear and intact from production to use. In addition, establish an information system to upgrade from batch management to each steel pipe management. Record the furnace number, steel grade, heat treatment process, geometric dimensions, flaw detection, and water pressure information of each steel pipe in the system file, which can be checked at any time during the production process.

(6) Automatic measurement of pipe end dimensions is required, with two cross sections of 5mm and 50mm away from the pipe end, and measurement point positions marked along the circumference. The automatic measurement and recording equipment for pipe end dimensions can greatly improve the accuracy and efficiency of detection.

(7) High requirements for production automation, automatic collection, organization, and uploading of information.

4. Process Plan and Equipment Selection for Deep Processing Production Line

In 2020, Yuantai Derun Steel Pipe Manufacturing Group, as a large domestic steel pipe production enterprise, recently launched the construction of a deep sea pipeline deep processing production line. Taking this project as an example, this article analyzes and summarizes its production process and equipment selection.

4.1 Process Plan

The product is positioned as high-strength seamless steel pipes for deep-sea pipeline pipes and marine engineering structures, with an annual output of 50000 tons; The product specifications are Ф 114.3~323.9 mm × 4.0~45.0 mm × 6 000~14 600 mm, steel grades are X42~X70, X42N~X60N, X42Q~X100Q. The raw steel pipe should be pre finished steel pipe or heat treated steel pipe that has passed the inspection after straightening and non-destructive testing; The length of the pipe material is a single length; The steel pipe has no defects, and the physical and chemical inspection results show that the performance of the raw steel pipe is qualified; The bending degree of the raw steel pipe is ≤ 1 mm/1000 mm, the outer diameter deviation is (-0.3%~+0.3%) D, and the wall thickness deviation is (-3.5%~+6.5%) t.

The production process flow is: loading, bulk material → pipe cutting Sizing → Pipe End Sizing → Pipe End Inner Surface Treatment → Pipe End Inner Surface Marking → Reading of Pipe End Mark No.1 → Hydrostatic Testing → Reading of Pipe End Mark No.2 → Ultrasonic Inspection of Pipe End → Reading of Pipe End Mark No.3 → Non destructive Testing of Pipe Body → Pipe End Chamfering → Reading of Pipe End Mark No.4 → Wet Magnetic Particle Testing of Pipe End → Pipe Rust Removal → Reading of Pipe End Mark No.5 → Geometric Dimension Measurement → Reading of Pipe End Mark No.6 → Measurement Weighing, etc. → UV painting and color banding → Reading of the 7 # pipe end mark → Groove printing, color ring → Reading of the 8 # pipe end mark → Final inspection, grinding → Finished product collection.

4.2 Equipment selection

The equipment selection for the deep processing production line of deep-sea pipeline pipes is shown in Table 6

|

NO(序号)

|

Device Name(设备名称) |

quantity(数量)

|

technical parameter (技术参数) |

|

1

|

Hydrostatic testing machine (水压实验机) |

1 set(1套)

|

Test pressure 5-207 MPa (700-30 000 psi), adjustable holding time for 5-300 seconds |

|

2

|

Pipe cutting machine (切管机) |

2 units(2台)

|

Fixed length accuracy±10 mm, with functions of cutting head, tail, fixed length, and slitting

|

|

3

|

Pipe end sizing machine (管端定径机) |

2 units(2台)

|

Conduct internal sizing within the range of 150mm at the end of the steel pipe for pipeline pipe products. After expanding the diameter of the steel pipe, the accuracy of the inner diameter is+0.6mm, with the highest steel grade of X00 (yield strength ≥ 960 MPa)

|

4 | Pipe non-destructive testing equipment(管体无损检测设备) | 1 set(1套) | Comprehensive inspection of the entire length of the steel pipe, including internal and external longitudinal and transverse, layering, and thickness measurement, with a thickness measurement accuracy of 0.05 mm |

5 | Pipe end ultrasonic testing equipment (管端超声波检测设备) | 2 units(2台) | The pipe end detection length is adjustable from 0 to 500 mm, with a detection coverage rate of 10%; Longitudinal, transverse, oblique φ 6 mm flat bottom hole layered inspection, thickness measurement accuracy 0.05mm |

6 | Flat head chamfering machine (平头倒棱机) | 2 units(2台) | Capable of achieving single angle and multi angle chamfering for steel pipes with a wall thickness of 45 mm and ensuring a blunt edge width of (160.8) mm, with water blowing. |

7 | Wet magnetic particle inspection of pipe end(管端湿磁粉探伤) | 2 units(2台) | Detect internal, external, longitudinal, and transverse defects, with clear display of circular rings and groove layers, and adjustable detection length of 0-500 mm |

8 | Geometric dimension measurement equipment(几何尺寸测量设备) | 2 units(2台) | Using optical methods to automatically measure the size of the pipe end, it can cover a length within 300 mm of the pipe end. The measurement position can be one or more sections of the pipe end, and the displacement of the section from the pipe end can be specified. The directly measured parameters include outer diameter and inner diameter, and the calculated parameters include wall thickness, outer diameter ovality, and inner diameter ovality. The measurement accuracy needs to reach 0.05 mm or higher; Adjustable measurement points (8-1000 points per section) |

9 | Rust remover(除锈机) | 1 units(1台) | |

10 | Measuring equipment(测量设备) | 1 set(1套) | Including functions such as length measurement, weighing, marking, internal marking at both ends, and full length external printing |

11 | Groove printing equipment(坡口打印设备) | 2 units(2台) | Print furnace number, batch number, pipe number, and other information on the conical surface of the groove, and have the function of coating color rings at both ends |

12 | UV painting device(UV涂漆装置) | 1 units(1台) | UV paint on the pipe body, with the function of applying two full-length color bands |

13 | Material tracking system(物料跟踪系统) | several(若干) | Including 2 sets of internal surface treatment equipment for pipe ends, 2 sets of steel pipe marking equipment, 8 sets of marking reading equipment, and several computer software and hardware |

14 | Non standard equipment(非标准设备) | several(若干) | Including transportation mechanisms such as roller tables, platforms, chain beds, and feeding mechanisms |

5 Our Strengths And Challenges

The machining process for deep processing of deep-sea pipeline pipes requires higher precision, more complex measurement and inspection processes, and higher automation requirements. At present, many domestic steel pipe enterprises have deep processing production lines for ordinary pipeline pipes, but there are few specialized deep processing production lines for deep-sea pipeline pipes. Yuantai Derun is one with this deep processing capability, but facing the increasingly complex deep-sea environment, it also brings us many challenges. Compared to peers, the existing production lines have the following advantages in producing deep-sea pipeline pipes:

(1) The equipment configuration is complete, with high equipment capacity and accuracy. In contrast, many domestic factories do not have automatic inner and outer diameter measurement equipment in their production lines, and the pressure of the hydraulic press cannot meet the requirements. They cannot achieve groove printing, track information one by one, and there are also many limitations in pipe end sizing machines and flaw detection equipment. Meanwhile, due to the large amount of equipment, it has also brought some challenges to our finances. However, the persistent Yuan Tai people, these are not problems.

(2) The inspection process is strict, the product manufacturing time is shortened, the occupied space is reduced, and the transportation is reduced. During the lifting and transportation of steel pipes, more attention is paid to protecting the surface and ends of the steel pipes, which can upgrade or qualify the product quality.

(3) The existing steel pipe production line cannot fully release production capacity for producing such deep-sea pipeline steel pipes.

(4) CNC automated production equipment has been completed, greatly saving labor, time and effort, reducing costs, high efficiency, and accuracy.

In a word, in order to improve the quality of deepwater pipeline products, Yuantai Derun Steel Pipe Manufacturing Group has already owned a professional deepwater pipeline production line, upgraded key equipment, such as flaw detection equipment, pipe end sizing equipment, automatic measuring equipment, and strengthened the construction and improvement of the enterprise resource planning management system. Dear valued customer, you can rest assured to contact us for the ordering and processing of deep-sea pipeline pipes.

18 results

ViewShowcase

Yuantai Derun steel pipe manufacturing group is a customized supplier for galvanized tube to slovakia

API 5L SMLS line pipe X42-X70 manufacturer YuantaiDerun can produce line pipes,low price,high quality,complete specifications.

API 5L line pipe manufacturer China yuantaiderun,our advantage is low price,high quality,fast delivery,complete specifications.

Black Steel Gas Pipe - Your Reliable Partner for OEM, ODM, Distributorship, and Wholesale.

YuantaiDerun steel pipe manufacturing group is a API 5L line tube factory ,line pipes,low price,high quality.

Introducing our flagship product: Seamless carbon steel pipes by Yuantai Derun, a trusted API 5L line tube manufacturer.

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Steel Pipe

- Steel Profile

- Steel Coil

- USE

- Structural steel pipe

- Fluid pipe

- Shape

- Square steel pipe

- Rectangular steel pipe

- Round steel pipe

- Shape tube

- Turface Treatment

- Black steel tube

- Pre galvanzied steel tube

- Hot dip galvanized steel tube

- Zinc aluminum magnesium coating steel tube

- Material

- Carbon steel pipe

- Alloy steel pipe

- Stainless steel pipe

- Standard

- EN10210

- EN10219

- ASTM A500

- ASTM A501

- ASTM A53

- ASTM A106

- ASTM A572

- ASTM A992

- JIS G3466

- AS/NZS 1163

- CSA G40.20

- CSA G40.21

- API 5L

- API 5CT

- Molding Process

- ERW steel pipe

- LSAW steel pipe

- Spiral welded steel pipe

- Seamless steel pipe

- Sales Attributes

- Sample list

- OEM

- ODM

- New arrival

- Basic style

- Star style

- Cross Section

- C channel

- Z channel

- U channel

- Round steel rod

- Rebar

- Angle steel

- H beam

- Raw material

- carbon steel profile

- Stainless steel profile

- Alloy steel profiles

- u channel

- Surface Treatment

- Zinc aluminum magnesium steel coil

- GI steel coil

- PPGI coil

- Stainless steel coil

- Steel plate

- Steel strip

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Phone

- *Title

- *Content