Contact Us To Get The Hot Product Catalog

We are constantly exploring products tailored for the structural steel pipe market.

Here, you will find a unique product line designed specifically for the global market that pursues excellence and quality, aimed at meeting your various needs. Our goal is to become a leading global manufacturer of structural steel pipes, providing every customer with the high-quality products and services they expect.

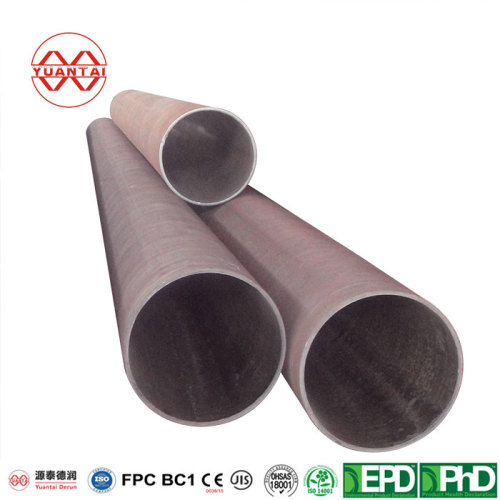

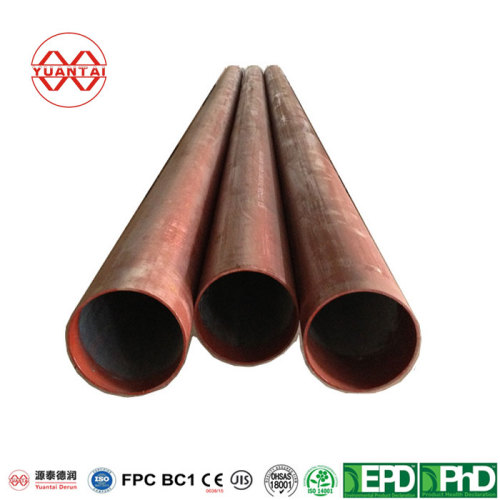

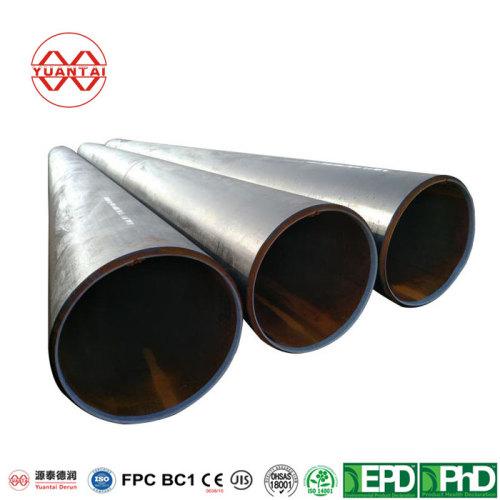

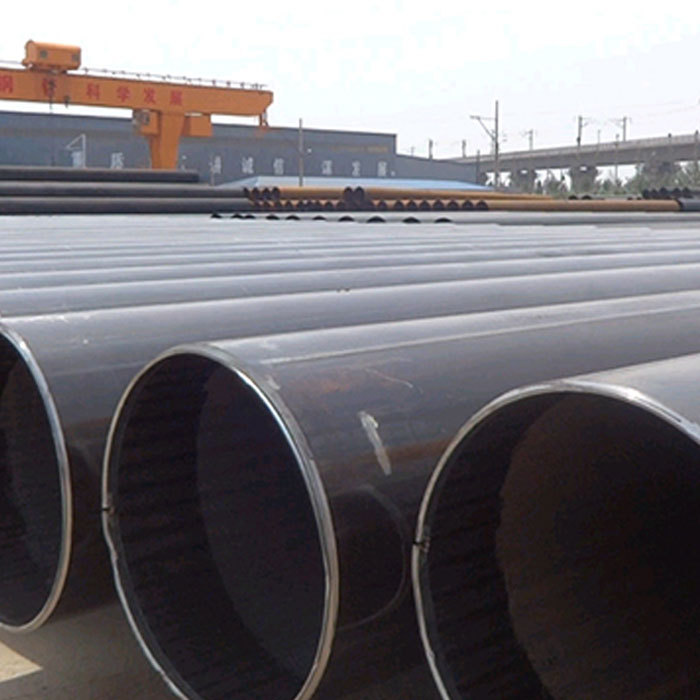

LSAW steel pipe

LSAW Steel Pipe

LSAW steel pipe is a type of steel pipe with longitudinal parallel welds.Refers to longitudinal submerged arc welded (LSAW or SAWL) pipes.Its other name is DSAW (Double Submerged Arc Welded) steel pipe.The production process of longitudinally welded pipes is simple, with high production efficiency, low cost, and rapid development. It is divided into UOE, RBE, and JCOE steel pipes.

China LSAW Steel Pipe Factory

Outside Diameter(O.D.): 406-1829mm(16"-72")

Wall Thickness(W.T.): 6-100mm

Length: 0.5-24M(Customized cutting of any length according to requirements)

Standard: API, ASTM, BS, DIN, JIS, API 5L, ASTM A53,DNV,ISO,GB,DEP,CSA.

Grade: API X42 X52 X60 X65 X70 GrA GrB GrC,S275J0H,S355JR,S355J0H,S355J2H,S355 S235 S420 S460 API 5L A-X100, GB/T9711 L190-L690

Tolerance: ±5%T or as required for wall thickness/<±0.1%T or as required for outside diameter.

Surface Treatment: Oil,Galvanized,Black ,Yellow Varnish coating or as required.

Certification: CE,EN,ISO,API,JIS,GB,BV,BC1,DNV,ABS,FPC,LEED,EPD,PhD,etc.

Production Cycle: About 30 days,Excluding LSAW steel pipes in stock.

MOQ: 2-5 Tons

Delivery Cycle: To South Africa: 45 days/To the Middle East: 30 days/To South America: 45 days/To North America: 30 days/To Russia: 7 days/To Europe: 45 days/To Korea: 5 days/To Japan: 5 days/To Vietnam: 15 days/To Thailand: 15 days/To India: 30 days/To Indonesia: 15 days/To Singapore: 15 days

Test: X ray test/UT test/Surface inspection/Flattening test/Magnetic particle testing/Water pressure testing/Chemical composition testing/Impact test/yield strength test/tensile strength test/elongation test/Blow Test/DWT Test

Transport:Equipped with professional loaders and convoys to ensure that goods are not damaged.

Payment method: TT/LC

Why Us?

LSAW Steel Pipe Specification Table

|

Outside Diameter(O.D.)

|

Wall Thickness(W.T.) |

Length(M)

|

|||||||

|

Inch

|

MM

|

Min.Yield Strength(Mpa) |

|||||||

|

Inch

|

MM

|

245(B) | 290(X42) | 360(X52) | 415(X60) | 450(X65) | 485(X70) | 555(X80) |

|

|

16

|

406

|

6.0-14.0 | 6.0-13.0 | 6.0-12.0 | 6.0-11.0 | 6.0-10.5 | 6.0-10.0 | 6.0-9.0 |

0.5-24M

|

18 | 457 | 6.0-15.0 | 6.0-14.0 | 6.0-13.0 | 6.0-12.0 | 6.0-11.5 | 6.0-11.0 | 6.0-10.0 | 0.5-24M |

20 | 508 | 6.0-16.0 | 6.0-15.0 | 6.0-14.0 | 6.0-13.0 | 6.0-12.5 | 6.0-12.0 | 6.0-11.0 | 0.5-24M |

22 | 559 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-14.0 | 6.0-13.5 | 6.0-13.0 | 6.0-12.0 | 0.5-24M |

24 | 610 | 6.0-18.0 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-14.5 | 6.0-14.0 | 6.0-13.0 | 0.5-24M |

26 | 660 | 6.0-19.0 | 6.0-18.0 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-15.0 | 6.0-14.0 | 0.5-24M |

28 | 711 | 6.0-20.0 | 6.0-19.0 | 6.0-18.0 | 6.0-17.0 | 6.0-16.5 | 6.0-16.0 | 6.0-15.0 | 0.5-24M |

30 | 762 | 7.0-21.0 | 7.0-20.0 | 7.0-19.0 | 7.0-18.0 | 7.0-17.5 | 7.0-17.0 | 7.0-16.0 | 0.5-24M |

32 | 813 | 7.0-22.0 | 7.0-21.0 | 7.0-20.0 | 7.0-19.0 | 7.0-18.5 | 7.0-18.0 | 7.0-17.0 | 0.5-24M |

34 | 864 | 7.0-23.0 | 7.0-22.0 | 7.0-21.0 | 7.0-20.0 | 7.0-19.5 | 7.0-19.0 | 7.0-18.0 | 0.5-24M |

36 | 914 | 8.0-24.0 | 8.0-23.0 | 8.0-22.0 | 8.0-21.0 | 8.0-20.5 | 8.0-20.0 | 8.0-19.0 | 0.5-24M |

38 | 965 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.0 | 8.0-21.5 | 8.0-21.0 | 8.0-20.0 | 0.5-24M |

40 | 1016 | 8.0-26.0 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.5 | 8.0-22.0 | 8.0-21.0 | 0.5-24M |

42 | 1067 | 8.0-26.0 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.5 | 8.0-22.0 | 8.0-21.0 | 0.5-24M |

44 | 1118 | 9.0-27.0 | 9.0-26.0 | 9.0-24.5 | 9.0-23.5 | 9.0-22.8 | 9.0-22.0 | 9.0-21.0 | 0.5-24M |

46 | 1168 | 9.0-27.0 | 9.0-26.0 | 9.0-24.0 | 9.0-23.5 | 9.0-22.8 | 9.0-22.0 | 9.0-21.0 | 0.5-24M |

48 | 1219 | 9.0-28.0 | 9.0-27.0 | 9.0-25.4 | 9.0-24.0 | 9.0-23.5 | 9.0-23.0 | 9.0-22.0 | 0.5-24M |

52 | 1321 | 9.0-28.0 | 9.0-27.0 | 9.0-25.4 | 9.0-24.2 | 9.0-23.5 | 9.0-23.0 | 9.0-22.0 | 0.5-24M |

56 | 1422 | 10.0-29.0 | 10.0-28.0 | 10.0-26.0 | 10.0-24.5 | 10.0-23.8 | 10.0-23.0 | 10.0-22.0 | 0.5-24M |

60 | 1524 | 10.0-29.0 | 10.0-28.0 | 10.0-26.0 | 10.0-24.5 | 10.0-23.8 | 10.0-23.0 | 10.0-22.0 | 0.5-24M |

64 | 1626 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 0.5-24M |

68 | 1727 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 0.5-24M |

72 | 1829 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 0.5-24M |

How Are LSAW Steel Pipes Made?

What Are The Applications Of LSAW Steel Pipes?

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Steel Pipe

- Steel Profile

- Steel Coil

- USE

- Structural steel pipe

- Fluid pipe

- Shape

- Square steel pipe

- Rectangular steel pipe

- Round steel pipe

- Shape tube

- Turface Treatment

- Black steel tube

- Pre galvanzied steel tube

- Hot dip galvanized steel tube

- Zinc aluminum magnesium coating steel tube

- Material

- Carbon steel pipe

- Alloy steel pipe

- Stainless steel pipe

- Standard

- EN10210

- EN10219

- ASTM A500

- ASTM A501

- ASTM A53

- ASTM A106

- ASTM A572

- ASTM A992

- JIS G3466

- AS/NZS 1163

- CSA G40.20

- CSA G40.21

- API 5L

- API 5CT

- Molding Process

- ERW steel pipe

- LSAW steel pipe

- Spiral welded steel pipe

- Seamless steel pipe

- Sales Attributes

- Sample list

- OEM

- ODM

- New arrival

- Basic style

- Star style

- Cross Section

- C channel

- Z channel

- U channel

- Round steel rod

- Rebar

- Angle steel

- H beam

- Raw material

- carbon steel profile

- Stainless steel profile

- Alloy steel profiles

- u channel

- Surface Treatment

- Zinc aluminum magnesium steel coil

- GI steel coil

- PPGI coil

- Stainless steel coil

- Steel plate

- Steel strip

- Name

- Mobile Phone

- *Title

- *Content