Contact Us To Get The Hot Product Catalog

We are constantly exploring products tailored for the structural steel pipe market.

Here, you will find a unique product line designed specifically for the global market that pursues excellence and quality, aimed at meeting your various needs. Our goal is to become a leading global manufacturer of structural steel pipes, providing every customer with the high-quality products and services they expect.

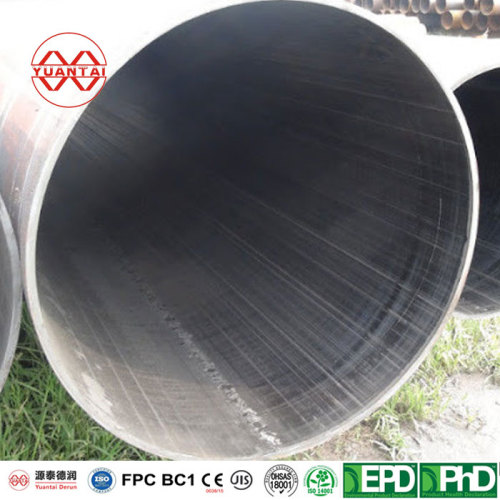

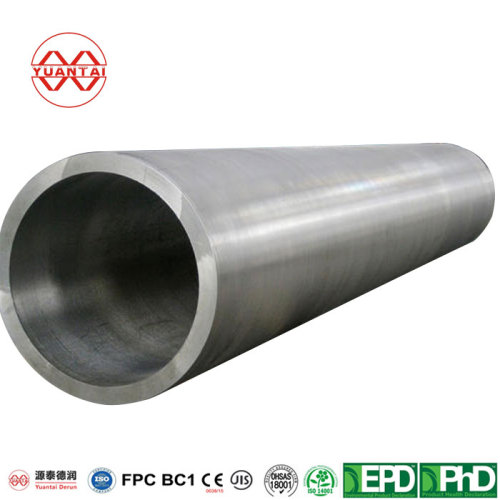

seamless steel pipe

Seamless steel pipes, known as the "blood vessels" of industry, are important raw materials for national industrial and national defense construction. The seamless steel pipes produced by Yuantai Derun have stable performance, reasonable prices, and guaranteed quality, making them a reliable seamless steel pipe supplier in China.Contact us immediately.

Seamless Pipe Detail:

Shape:round,square,rectangular or shaped.

Out Diameter(φ):1/4 inch-36 inch(6.35-914mm)

Wall Thickness:1.25-50mm(SCH10,SCH40,SCH60,XS,SCH80,STD,XXS,SCH120,SCH160)

Length: 0.5-24M or cut according to requirements

Tolerance:±%10 or According to customer requirements

MOQ:2-5 Tons

Payment Term: TT/LC

Delivery time:7-40 days

Packing:Steel strip bundling, PVC wrapped fabric

Capacity: 50000 tons per month

Standard: API 5L PSL1/PSL2 Gr.b, X42/46/52/56/65/70,API 5CT,GB/T9711,ASTM A53,ASTM A106,ASTM A519,etc.

Brand: Yuantai Derun or OEM

Type: Hydraulic pipe,Boiler tubes,Fluid tube,Fire pipe,

Conduit,Structural tube,Mechanical tube.

Characteristics Of Seamless Steel Pipes

High strength

Seamless steel pipes are made of a single billet, and their overall strength is superior to that of welded pipes. Has high tensile strength and elastic modulus, able to withstand high pressure and high temperature working conditions.

Excellent mechanical performance

Seamless steel pipes have good mechanical properties, are easy to machine, do not deform during repeated use, maintain high elasticity, have no memory, and are not prone to cracking and leakage.

Strong Corrosion Resistance

The corrosion resistance of seamless steel pipes has been further improved due to the production process of hot rolling or first hot rolling and then cold rolling, especially in terms of acid, alkali, salt, and atmospheric corrosion resistance, with excellent performance.

Environmentally friendly and recyclable

Seamless steel pipes have good recyclability and reusability, meet environmental requirements, and in the long run, their cost-effectiveness is significant.

Seamless Steel Pipe Application

》Transporting oil

》Transporting natural gas

》Transporting gas

》Transporting water

》Transporting solid materials

》Manufacturing structural components

》Mechanical parts

》Drill pipe

》Automobile transmission shaft

》Bicycle frame

》Building steel

》Scaffold

》Manufacturing circular parts

》Shipbuilding

》Fertilizer industry

》Heat exchanger

》Food manufacturing

》Pump, hydraulic cylinder

》Flange

》Pressure vessel

》High temperature container

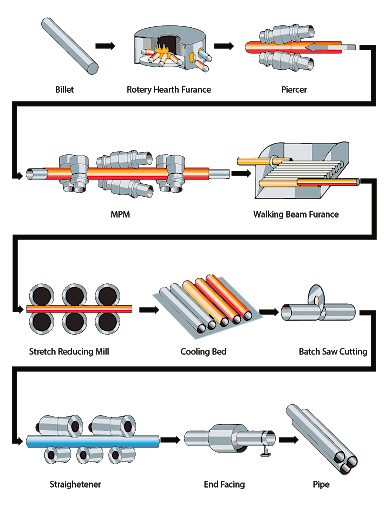

Seamless Pipe Manufacturing Process

The main production processes of hot-rolled seamless steel pipes include: preparation and inspection of pipe billets - heating of pipe billets - perforation - rolling of pipes - reheating of steel pipes - sizing (reduction) - heat treatment - straightening of finished pipes - finishing - inspection (non-destructive, physical and chemical, bench inspection) - storage.

The main production processes of cold-rolled (drawn) seamless steel pipes include billet preparation, acid pickling and lubrication, cold rolling (drawing), heat treatment, straightening, finishing, and inspection. The production process of cold-rolled seamless steel pipes is generally more complex than hot rolling

Standards & Grades For Seamless Steel Pipes

ASTM Standards For Seamless Steel Pipes | |||

|

Standard Executive

|

Grade/Material

|

Product Name

|

|

|

ASTM A53

|

A,B

|

Black and Hot-Dipped Galvanized Steel Pipes Welded and Seamless

|

|

|

ASTM A106

|

A,B

|

Seamless Carbon Steel for High Temperature Service

|

|

|

ASTM A179

|

Low Carbon Steel

|

Seamless Cold-Drawn Low-Carbon Steel Heat Exchanger and Condenser Tubes

|

|

ASTM A192 | Low Carbon Steel | Seamless Carbon Steel Boiler Tubes for High Pressure | |

ASTM A210 | A1, C | Seamless Medium-Carbon and Alloy Steel Boiler and Superheater Tubes | |

ASTM A213 | T5, T11, T12, T22 ,TP 347H | Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes | |

ASTM A312 | TP304/304L, TP316/316L | Seamless Steel Pipe for Stainless Materials | |

ASTM A333 | Gr.6 | Seamless and Welded Steel Pipe for Low-Temperature Service | |

ASTM A335 | P9, P11, P22 | Seamless Ferritic Alloy Steel Pipe for High-Temperature Service | |

ASTM A519 | 4130,4140 | Seamless Carbon and Alloy Steel for Mechanical Tubing | |

ASTM A789 | Seamless Ferritic/Austenitic Stainless Steel Tubing for General Service | ||

API Standards For Seamless Steel Pipes | |||

|

Executive Standard

|

Grade / Material

|

Product Name

|

|

|

API Spec 5CT

|

J55, K55, N80, L80,C90, C95, T95, P110, M65

|

Spectification for Casing and Tubing

|

|

|

API Spec 5L PSL1

|

A,B X42, X46, X52, X56, X60, X65,. X70

|

Specification for Line Pipe

|

|

|

API Spec 5L PSL2

|

A,B X42, X46, X52, X56, X60, X65 X70

|

Specification for Line Pipe

|

|

DIN / EN Standards For Seamless Steel Pipes | |||

|

Executive Standard

|

Grade / Material

|

Product Name

|

|

|

DN 17175/EN10216-2

|

ST35, ST45, ST52, 13CrMo44

|

Seamless Steel Tube for Elevated Temperature

|

|

|

DIN 2391/EN10305-1

|

St35, St45, St52

|

Cold Drawn Seamless Precision Pipe

|

|

|

DIN 1629/EN10216-1

|

St37, St45, St52

|

Seamless Circular unalloyed Steel Pipes Subject to Special Requirements

|

|

FAQ:

What is a seamless steel pipe?

Seamless steel pipe is made of the whole round steel perforation, the surface of the steel pipe without welds is called seamless steel pipe

What is difference between seamless and welded pipe?

The seamless steel pipe is produced via hot rolling and cold rolling, and has no seams as the name suggests. In contrast, a welded pipe is made by rolling a steel coil to the required gauge thickness, which results in a seam on the pipe's body.

What are the disadvantages of seamless pipes?

The most obvious defect of seamless steel pipes is that the accuracy of pipe dimensions is not high before cold rolling or cold drawing treatment.

In addition, there is also a long production time. Producing a welded pipe with the same diameter also requires a shorter production time.

what Are the meaning of CDS and HFS?

CDS means cold drawn seamless. HFS means hot finished seamless.

Is seamless Steel pipe Stronger than Welded Steel Pipe?

Yes.The strength of seamless steel pipe is superior to that of welded steel pipe under the same conditions. The reason is that the seamless pipe is made of a steel perforated extrusion moulding, there is no any weld. Welded pipe, however, there is a parent material and welding raw materials, in the production process, welded pipe weld even if the fusion of the best is not as good as a parent material moulding to the perfect.

34 results

ViewShowcase

ASTM A572 Seamless carbon steel pipes for all your industrial needs - OEM, ODM, wholesale, and distribution options available.

Seamless Steel Pipe & Tube,Carbon Seamless Steel Pipe,SMLS Pipe & Tube, CS Seamless Pipe,Black Seamless Pipe, GI Seamless Pipe

Factory YuantaiDerun can produce all kinds of seamless steel pipe that as known as the "blood vessel" of industry

seamless steel pipe supplier yuantaiderun(oem odm obm),it can produce all kinds of seamless steel pipe,low price,high quality

seamless steel pipe mill China yuantaiderun(accept oem odm obm),low price,high quality,fast delivery,complete specifications.

seamless steel pipe manufacturers China yuantaiderun(oem odm obm),low price,high quality.

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Steel Pipe

- Steel Profile

- Steel Coil

- USE

- Structural steel pipe

- Fluid pipe

- Shape

- Square steel pipe

- Rectangular steel pipe

- Round steel pipe

- Shape tube

- Turface Treatment

- Black steel tube

- Pre galvanzied steel tube

- Hot dip galvanized steel tube

- Zinc aluminum magnesium coating steel tube

- Material

- Carbon steel pipe

- Alloy steel pipe

- Stainless steel pipe

- Standard

- EN10210

- EN10219

- ASTM A500

- ASTM A501

- ASTM A53

- ASTM A106

- ASTM A572

- ASTM A992

- JIS G3466

- AS/NZS 1163

- CSA G40.20

- CSA G40.21

- API 5L

- API 5CT

- Molding Process

- ERW steel pipe

- LSAW steel pipe

- Spiral welded steel pipe

- Seamless steel pipe

- Sales Attributes

- Sample list

- OEM

- ODM

- New arrival

- Basic style

- Star style

- Cross Section

- C channel

- Z channel

- U channel

- Round steel rod

- Rebar

- Angle steel

- H beam

- Raw material

- carbon steel profile

- Stainless steel profile

- Alloy steel profiles

- u channel

- Surface Treatment

- Zinc aluminum magnesium steel coil

- GI steel coil

- PPGI coil

- Stainless steel coil

- Steel plate

- Steel strip

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Mobile Phone

- *Title

- *Content