Home / All / galvanized steel pipe / Hot Dipped Galvanized Steel Pipe / hot galvanized square pipe ASTM A 500 B (OR) S275 JR Square Hollow Sections

hot galvanized square pipe ASTM A 500 B (OR) S275 JR Square Hollow Sections

Detail Information

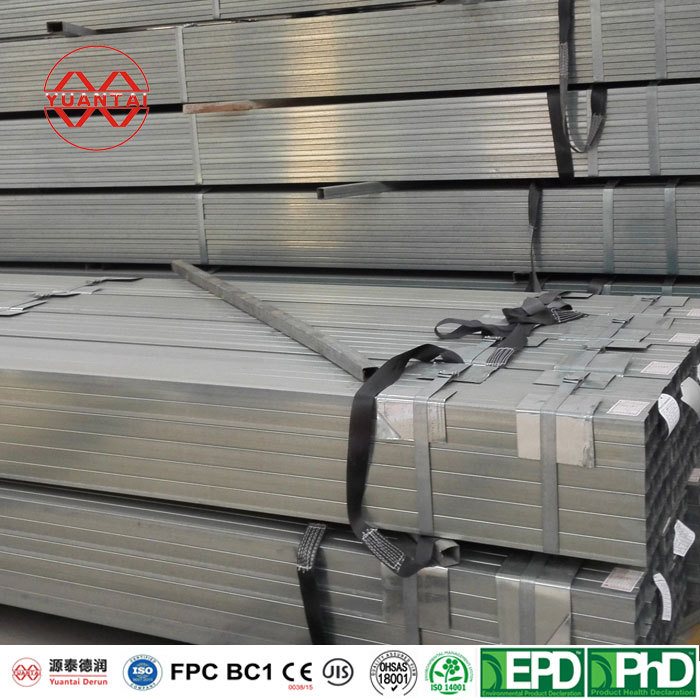

hot galvanized square pipe ASTM A 500 B (OR) S275 JR Square Hollow Sections

Hot Galvanized Square Pipe: Powering Structures with Strength

In this article, we will delve into the world of hot galvanized square pipes, specifically focusing on the ASTM A500B and S275 JR square hollow sections. We will explore their characteristics, advantages, applications, and the importance of reliable steel pipe manufacturers and square steel pipe factories. Additionally, we will discuss the significance of choosing the right square tube thickness and provide installation and maintenance tips. Join us as we uncover the secrets behind these powerful structural components.

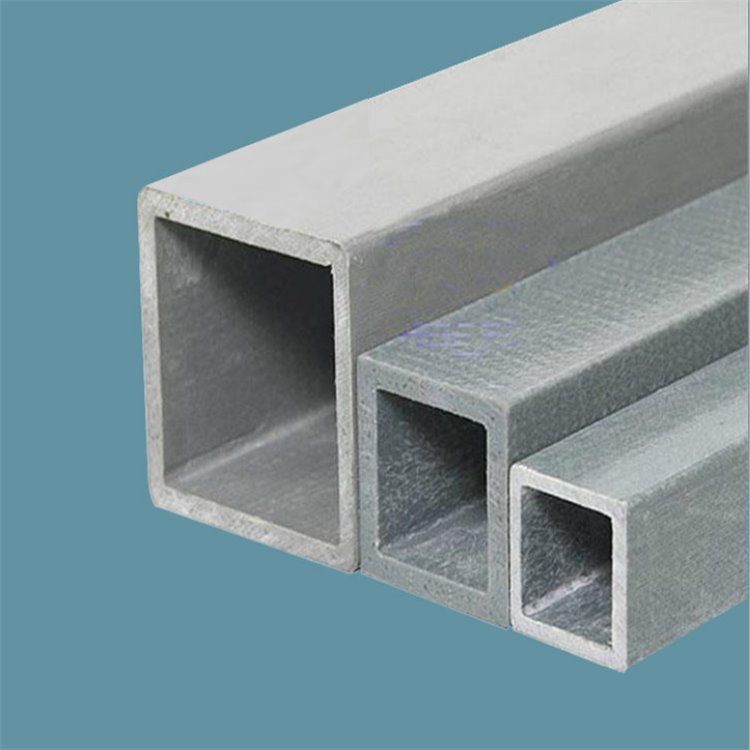

Overview of Hot Galvanized Square Pipe

Hot galvanized square pipes are robust steel pipes that undergo a galvanization process to enhance their durability and resistance to corrosion. This coating is achieved by immersing the pipes in a bath of molten zinc, creating a protective layer that shields the underlying steel from harsh environments.

Chemical composition and thermal analysis

Element |

Composition, %

|

||||

GradesA, B,and D | Grade C | ||||

Heat Analysis | Product Analysis | Heat Analysis | Product Analysis | ||

Carbon, maxA | 碳,最大值 | 0.26 | 0.30 | 0.23 | 0.27 |

Manganese, maxA | 锰,最大值 | 1.35 | 1.40 | 1.35 | 1.40 |

Phosphorus, max | 磷,最大值 |

0.035

|

0.045

|

0.035

|

0.045

|

Sulfur, max | 硫,最大值 |

0.035

|

0.045

|

0.035

|

0.045

|

Copper, minB | 铜,最大值 |

0.20

|

0.18

|

0.20

|

0.18

|

Understanding ASTM A500B Square Hollow Sections

ASTM A500B hollow sections are a popular choice for various construction projects. These sections are made from carbon steel and comply with the ASTM A500 standard, ensuring high-quality, structurally sound components. We will explore the advantages and applications of these square hollow sections in detail.

Exploring S275 JR Square Hollow Sections

S275 JR square hollow sections, also known as S275JRH, offer another excellent option for structural applications. Manufactured from mild steel, these sections provide strength and versatility. We will delve into the properties and of S275 JR square hollow sections, highlighting their key benefits.

Importance of Steel Pipe Manufacturer

Choosing a reliable steel pipe manufacturer is crucial to ensure the quality and performance of hot galvanized square pipes. A reputable manufacturer adheres to strict quality control processes, uses high-grade materials, and employs advanced manufacturing techniques. We will discuss the importance of selecting the right manufacturer and the factors to consider during the decision-making process.

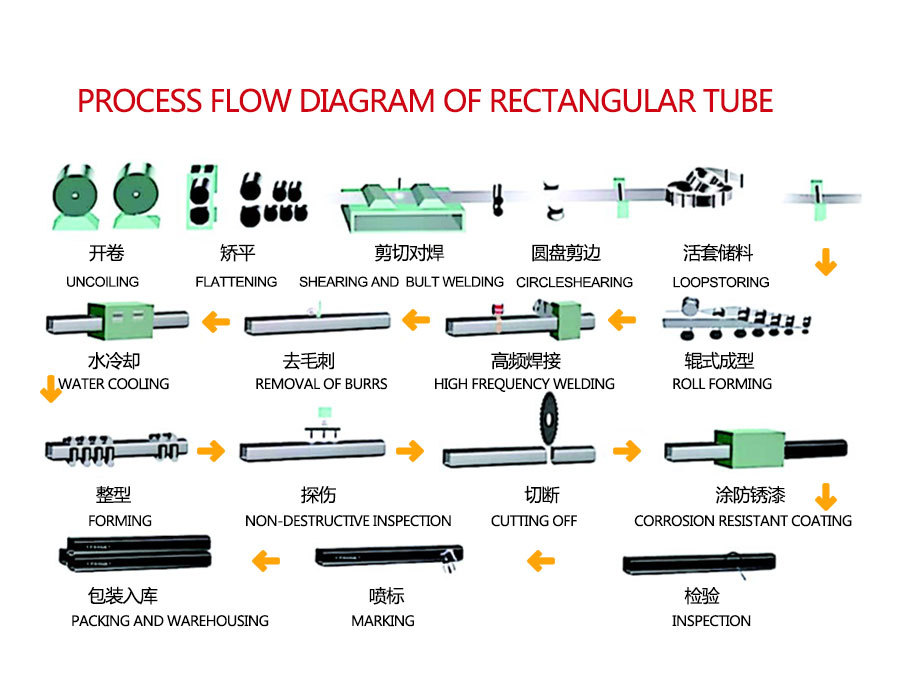

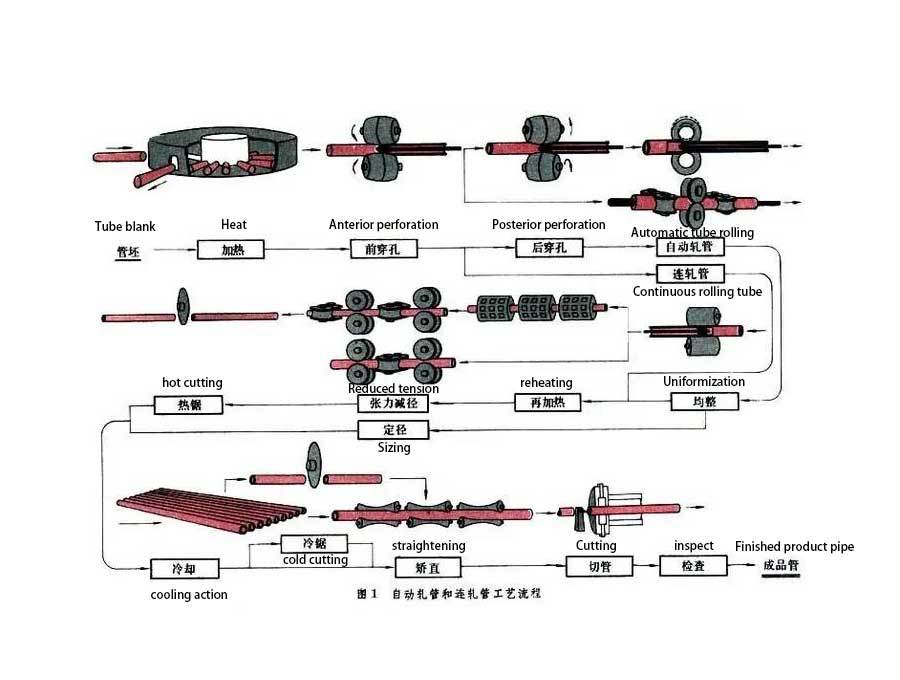

Manufacturing process( Advantages Hot Galvanization )

Hot galvanization offers numerous advantages for square pipes. The protective zinc coating not only safeguards against corrosion but also provides increased longevity and durability. We will discuss the specific benefits of hot galvanization and why it is a popular choice for square pipes.

Welding pipe manufacturing process and Seamless Pipe Manufacturing Process

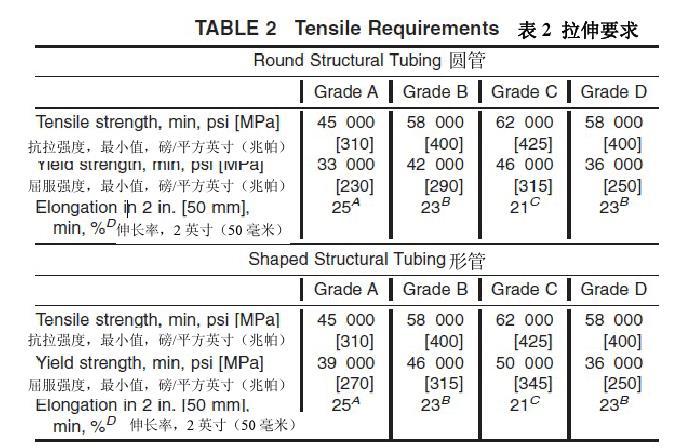

Tensile requirements

TABLE 2 Tensile Requirements

Flattening test

The flattening test is required for circular structural pipes, and is not required for other shaped structural pipes.

For circular welded pipes, the specimen must be at least 4 inches (100 millimeters) cold flattened between two parallel plates in three steps, with the weld seam at 90 ° to the direction of force.

The first step is a ductility test of the weld seam, with no cracks or fractures on the inner and outer surfaces of the sample until the distance between the two plates is less than two-thirds of the outer diameter of the pipe.

The second step is to ensure that there are no cracks or fractures on the inner and outer surfaces of the base material until the distance between the two plates is less than half of the outer diameter of the pipe, unless otherwise specified.

The third step is stability testing, and the flattening behavior continues until the sample breaks or the relative pipe wall of the sample comes into contact. Thin, insufficiently sturdy raw materials or incomplete welding will be shown throughout the flattening test, which will serve as evidence of product failure.

For seamless circular structural pipes with an outer diameter of 23/8 inches (60 millimeters) and above, the sample length should not be less than 21/2 inches (65 millimeters) and should be cold flattened between two parallel plates in two steps.

The first step is the ductility test, where there are no cracks or fractures on the inner and outer surfaces, except as specified in 10.5, until the distance between the two plates is less than the H value. The calculation formula is as follows: H=(1+e) t (e+t/D) (1), H=distance between the pressure plates, inches (millimeters), e=deformation per unit length (fixed values according to steel grade, A grade 0.09, B grade 0.07, C grade 0.06), t=specified wall thickness, inches (millimeters), E=deformation per unit length (with fixed values according to steel grade, A grade 0.09, B grade 0.07, C grade 0.06), t=specified wall thickness, inches (millimeters), D=specified pipe outer diameter, inches (millimeters)

The second step is stability testing, where the flattening behavior continues until the sample breaks or the relative pipe wall of the sample comes into contact. Thin, insufficiently sturdy raw materials or incomplete welding will be shown throughout the flattening test, which will serve as evidence of product failure.

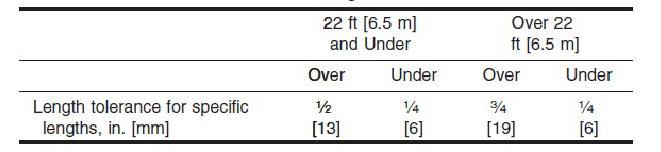

Length tolerance

TABLE 4 Length Tolerances for Specific Lengths of Structural Tubing

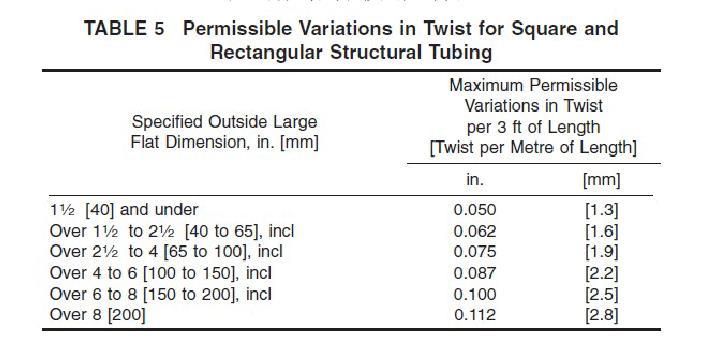

Permissible Variations in Twist for Square and Rectangular Structural Tubing

Benefits of Square Steel Pipe Factory of hot galvanized square pipe ASTM A 500 B (OR) S275 JR Square Hollow Sections

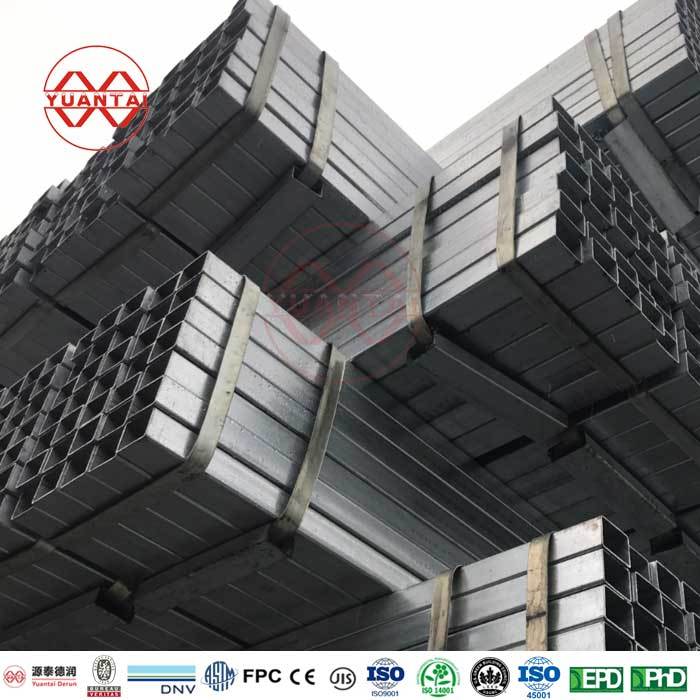

Square steel pipe factories play a vital role in meeting the growing demand for square pipes. These specialized facilities leverage their expertise, machinery, and resources to produce high-quality square steel pipes at scale. We will explore the advantages of sourcing from square steel pipe factories and the benefits they offer to customers.

The pipe orifice is flat and free of burrs

Uniform galvanizing of the pipe surface

Uniform wall thickness of steel pipes with high accuracy

Factors to Consider When Choosing Square Tube Thickness

Determining the appropriate square tube thickness is essential to ensure structural integrity. Several factors, including load requirements, environmental conditions, and design considerations, influence this decision. We will discuss these factors in detail, providing insights into selecting the optimal thickness for various applications.

Complete specifications, large stock of steel pipes in stock

The inner and outer walls of the steel pipe are smooth and flat

Steel pipes are delivered quickly in their own transportation fleet, ensuring delivery time

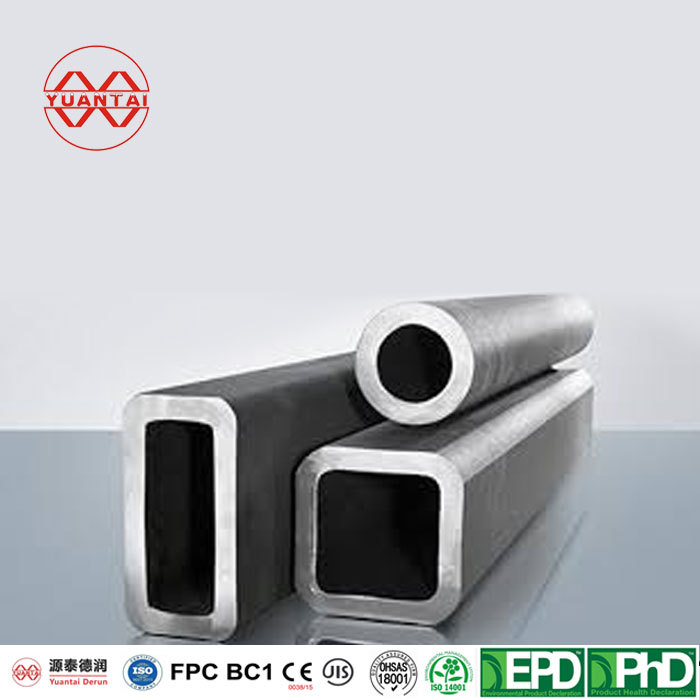

Steel tube samples of Yuantai Derun

Applications of Square Steel Pipes

Square steel pipes find extensive use across diverse industries and applications. From construction and infrastructure projects to furniture manufacturing and automotive applications, we will explore how square steel pipes provide structural support, enhance aesthetics, and offer cost-effective solutions.

BRIDGE CONSTRUCTION

Hong Kong-Zhuhai-Macao Bridge,Our products are involved in the construction of bridges. It is a bridge and tunnel project connecting Hong Kong, Zhuhai, Guangdong and Macao in China.

BUILDING CONSTRUCTION

SINGAPORE GOOGLE BUILDING,From 2018 to 2019, we provided steel pipes with hollow section profiles for the construction of Google building in Singapore

Installation and Maintenance Tips

Proper installation and regular maintenance are crucial for ensuring the long-term performance of square steel pipes. We will provide practical tips and best practices to consider during installation, as well as guidelines for maintaining the galvanized coating and addressing potential issues.

Pricing Factors for Square Steel Pipes

Pricing for square steel pipes can vary based on several factors. We will discuss the key determinants, including raw material costs, manufacturing processes, market demand, and other influential factors. Understanding these aspects will help customers make informed decisions and find the right balance between cost and quality.

Conclusion

Hot galvanized square pipes, such ASTM A500B and S275 JR square hollow sections, offer remarkable strength, durability, and corrosion resistance. Choosing a reliable steel pipe manufacturer and square steel pipe factory is crucial to ensure the highest quality products. Considering factors like square tube thickness and understanding the benefits of hot galvanization further enhances the effectiveness of these structural components. With their versatile applications and comprehensive advantages, hot galvanized square pipes continue to shape the construction industry.

FAQs

Q1: Can hot galvanized square pipes be used in outdoor applications?

A: Yes, hot galvanized square pipes are well-suited for outdoor applications due to their excellent corrosion resistance.

Q2: Are ASTM A500B and S275 JR square hollow sections interchangeable?

A: While both options offer similar structural capabilities, they may have different specifications that need to be considered during design and engineering.

Q3: How often should the galvanized coating be maintained?

A: The frequency of maintenance depends on various factors, such as environmental conditions and the level of exposure to corrosive elements. Regular inspections and prompt maintenance can help prolong the lifespan of the galvanized coating.

Q4: Can square steel pipes be customized for specific applications?

A: Yes, square steel pipes can be customized in terms of dimensions, coatings, and other specifications to meet specific project requirements.

Q5: What are the benefits of sourcing from a square steel pipe factory instead of a general steel pipe manufacturer?

A: Square steel pipe factories specialize in the production of square pipes, offering expertise, efficiency, and cost-effectiveness compared to general steel pipe manufacturers.

Review

- Loading...

Related Products

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Phone

- *Title

- *Content

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Phone

- *Title

- *Content