Home / All / square steel pipe / Wholesale 1 1/4 Square Tubing | Premium Carbon Steel Pipes - OEM & ODM Services for Distributors and Agents | Leading Manufacturer of Rectangular Steel Pipes in China

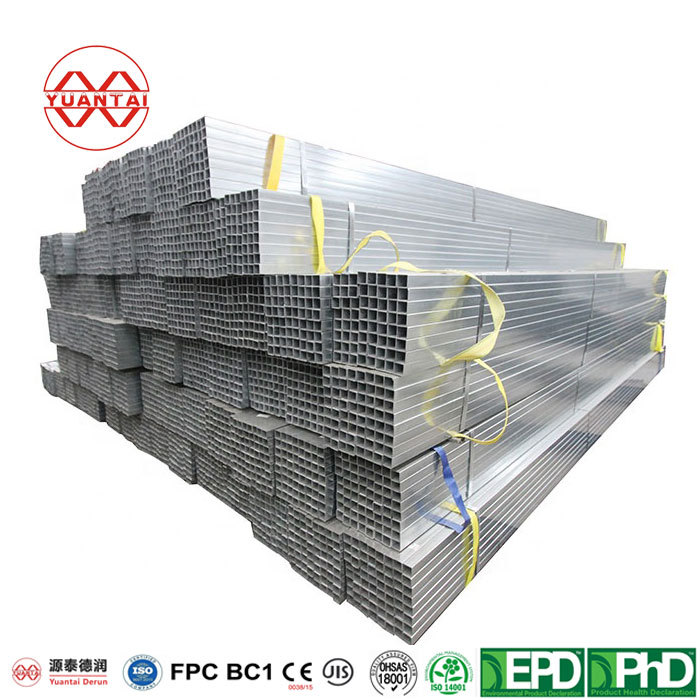

Wholesale 1 1/4 Square Tubing | Premium Carbon Steel Pipes - OEM & ODM Services for Distributors and Agents | Leading Manufacturer of Rectangular Steel Pipes in China

Detail Information

1 1/4 Square Tubing

1 1/4 Square Tubing is one of the most widely used materials in construction and manufacturing due to its strength, durability, and versatility. When it comes to structural applications, 1 1/4 inch square tubing is a popular choice. In this article, we will dive into the world of square tube steel, exploring its different sizes, applications, and advantages.

1 1 4 Square Steel Tubing Coating

In practice, we can select the appropriate coating according to the application environment.

1. Particularly harsh environments

We should choose hot-dip galvanizing 1 1 4 square steel tubing

2. General wet environment

You can choose pre-galvanized 1 1/4 inch square tubing

3. Salt spray environment

You can choose galvanized aluminum magnesium 1 1 4 inch square tubing

Free 1 1/4 Square Steel Tubing Samples For You

At Yuantai Derun, we make free samples of 1 1/4 Square Steel Tubing for you in lengths up to 20 CM, and you only need to pay one shipping fee to get our free samples.

1 1/4 Square Tubing Steel Application

1.building structures 2. Furniture 3 Agricultural machinery 4. Chassis 5 Truck carriage 5. Fitness equipment 6 Guardrail 7 Home decoration 8 Electric tricycle skeleton

Review

- Loading...

Related Products

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Phone

- *Title

- *Content

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Phone

- *Title

- *Content