RHS 150x100x8mm BS EN10219 S275J2H MS Rectangular Pipe

Detail Information

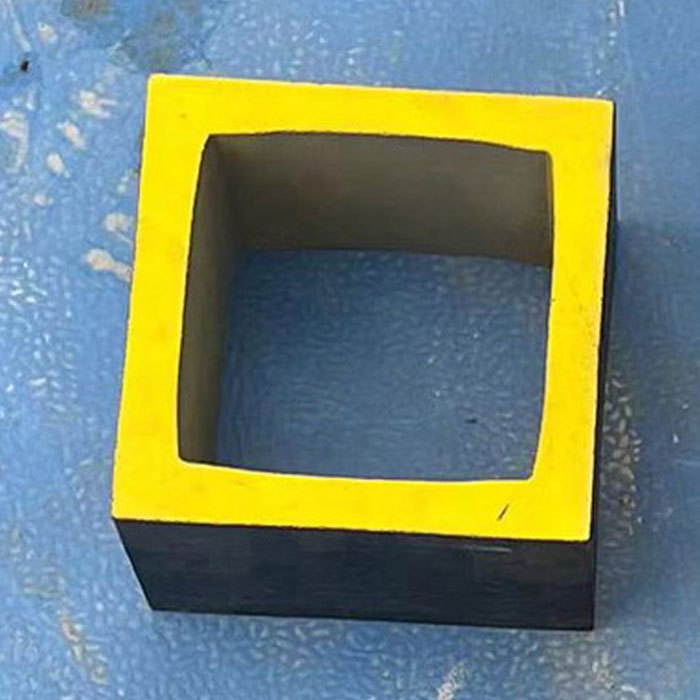

RHS 150x100x8mm BS EN10219 S275J2H MS Rectangular Pipe

RHS 150x100x8 mm BS EN10219 S275 J2H MS Rectangular Pipe is a very popular industry basic component known for its strength, durability and versatility. Different types of RHS 150x100x8 mm BS EN10219 S275 J2H MS Rectangular Tube have different unique functions and applications. The RHS 150x100x8mm BS EN10219 S275 J2H MS Rectangular Tube produced by Yuantai Derun has the advantages of tight welds, excellent load-bearing performance, and flexible customization. Global steel pipe buyers are welcome to consult and order.

Ms Rectangular Tube Sizes

In addition to RHS 150x100x8 mm BS EN10219 S275 J2H MS Rectangular Pipe, Yuantai Derun can also produce the following Ms Rectangular Tube Sizes.

|

Standard

|

Steel Grade

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M) |

|

EN10219

|

S275 J2H

|

10*10-1200*1200

|

0.5-60

|

0.5-26.5 |

Ms Rectangular Tube Making Process

At Yuantai Derun, Ms Rectangular Tube Making Process mainly has the following methods:

1. direct forming technology

2. Technology of changing round pipe into square pipe

3. Round first and then square technology Ask for molding technology now

Heat Treatment

At Yuantai Derun, in order to eliminate the internal stress of Ms Rectangular Tube and improve the performance of rectangular tubes, we can also provide customers with a variety of heat treatment methods, mainly including normalizing, annealing, quenching, tempering, corner heating and other heat treatment. Send your request immediately

Chemical Composition

Carbon ≤ 0.20%, silicon ≤ not required, manganese ≤ 1.50%, phosphorus ≤ 0.030%, sulfur ≤ 0.030%, nitrogen ≤ not required

Mechanical Properties

3mm<wall thickness ≤ 16mm: yield strength ≥ 275MPa, tensile strength ≥ 410-560MPa, elongation ≥ 20%

16mm<wall thickness ≤ 40mm: yield strength ≥ 265MPa, tensile strength ≥ 410-560MPa, elongation ≥ 20%

Coating

Yuantai Derun can provide a variety of coating treatments for RHS 150x100x8mm BS EN10219 S275J2H MS Rectangular Pipe. The purpose is to protect MS Rectangular tube from corrosion. The main forms include oiling, painting, and hot-dip galvanizing. Send coating requirements immediately.

Pipe Oiling

Tube Spray Painting

Tube Hot Dip Galvanizing

Flexible Customization Options

For RHS 150x100x8 mm BS EN10219 S275 J2H MS Rectangular Pipe, you can also flexibly customize the following options:

1. length

You can flexibly customize the length to meet your project requirements.

2. processing services

You can flexibly customize some processing services, such as punching, cutting, welding assembly, bending and other additional processing services.

3. shape

You can flexibly customize the shape of low carbon rectangular pipes. Common shapes are right-angled rectangular steel pipes and arc-angled rectangular steel pipes. Technical engineers can turn rectangular steel pipes into right-angled rectangular pipes through four-corner heating technology.

Cases And Application

BS EN10219 S275J2H MS Rectangular Pipe produced by Yuantai Derun is used in many world-renowned projects. For example, the Million Missile Land Improvement Project in Egypt and the New CBD Project in Cairo, Egypt. In fact, BS EN10219 S275 J2H MS Rectangular Pipe products are very excellent in both strength and toughness, and they are often used in the following industries.Such as:

1. Structural engineering

In the construction field, S275J2H rectangular steel pipes are often used to build large frames, beams, columns and other structures. Its good shaping and toughness make buildings safer and more stable when subjected to external forces such as earthquakes.

2. Mechanical Engineering

In the industrial field, S275J2H rectangular steel pipes are used as a support structure for industrial equipment such as equipment brackets and conveyor belt brackets to ensure long-term stable operation of the equipment.

GREENHOUSE CONSTRUCTION

From 2017 to 2018, we provided 75000 tons of steel pipe products for the green house of the million feidan land improvement project in Egypt.

CBD business district building

From 2019 to 2020, we provided our steel pipe products for the building development of CBD business district buildings in Cairo, Egypt

FAQS (Frequently Asked Questions)

How can I choose the correct dimensions of BS EN10219 S275J2H MS Rectangular Pipe for my project?

The size specifications of BS EN10219 S275J2H MS Rectangular Pipes can be summarized into two dimensions: outer diameter and wall thickness. Specifically, according to the size of the outer diameter, it can be divided into three types.

The first type is a super large rectangular steel pipe, with an outer diameter of AXB greater than 400 square millimeters and a wall thickness of 6mm ^~25mm;

The second type is large rectangular steel pipes, with an outer diameter of AXB between 100 ^ 400 square millimeters and a thickness of 6mm ^~14mm;

The third type is small rectangular steel pipes, which have an outer diameter of AXB less than or equal to 100 square millimeters and a thickness of 0 5mm ^~6mm.

For specially made rectangular steel pipes, according to processing and usage requirements, the outer diameter can be customized to 10-800 square millimeters, such as sizes within 0.5-20m. In the specification design, it is necessary to ensure that the strength of the rectangular steel pipe meets the requirements, adopt a reasonable shape, reduce material consumption and weight, and consider the existing production capacity to continuously improve the process and reduce production costs.

In addition, in order to reduce the supply cost of specific size specifications for rectangular steel pipes, rectangular steel pipe brands will adopt a compromise plan based on technical and economic considerations of "production capacity", "meeting market demand", and "setting prices" to determine the optimal size specifications for rectangular steel pipes.

What are the advantages of using MS Rectangular Pipes over other types of steel pipes?

The annealing structure of martensite tube is composed of ferrite and pearlite, which reduces its strength, hardness, ductility, and toughness. Therefore, it can have good cold formability, including cold forming methods such as curling, bending, stamping, etc. This type of steel has good weldability. The low carbon content hardness of MS tubes is very low and their machinability is poor, and quenching can improve their machinability. However, for the manufacturing of steel pipes, it is very durable. Different types of steel are used in many industries because they can withstand pressure, so the pressure rarely increases, leading to cracking or bending. They can be used for underwater pipelines because they are corrosion-resistant. It can maintain considerable tensile strength and durability of thick steel under high pressure. These steel pipes are used in various industries.

Can I use a MS rectangular tube weight calculator to estimate the weight of steel tubes?

Yes.Square and rectangular (rectangular) cross-section carbon steel:

Weight unit per meter: kg/m (kg/m)&lb/ft (lb/ft) Formula: kg/m=(Oc -4Wt) * Wt * 0.00785

Among them: Oc is the outer circumference, Wt is the wall thickness; Square Oc=4 * a Rectangle Oc=2a+2b a, where b is the side length

Calculation of the weight of circular cross-section steel pipes

Formula: kg/m=(Od Wt) * Wt * 0.02466, where Od is the outer diameter Wt is the wall thickness

How To Find ms rectangular pipe dealers?

In fact, it is very simple. You can go to the local metal building materials supermarket or hardware city and find an agent for low-carbon steel rectangular pipes.

Is Yuantai Derun a ms rectangular pipe supplier in lagos ?

No,Yuantai Derun is not a ms rectangular pipe supplier in lagos,Yuantai Derun is the largest Ms Rectangular Pipe Supplier In China.

Review

- Loading...

Related Products

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content