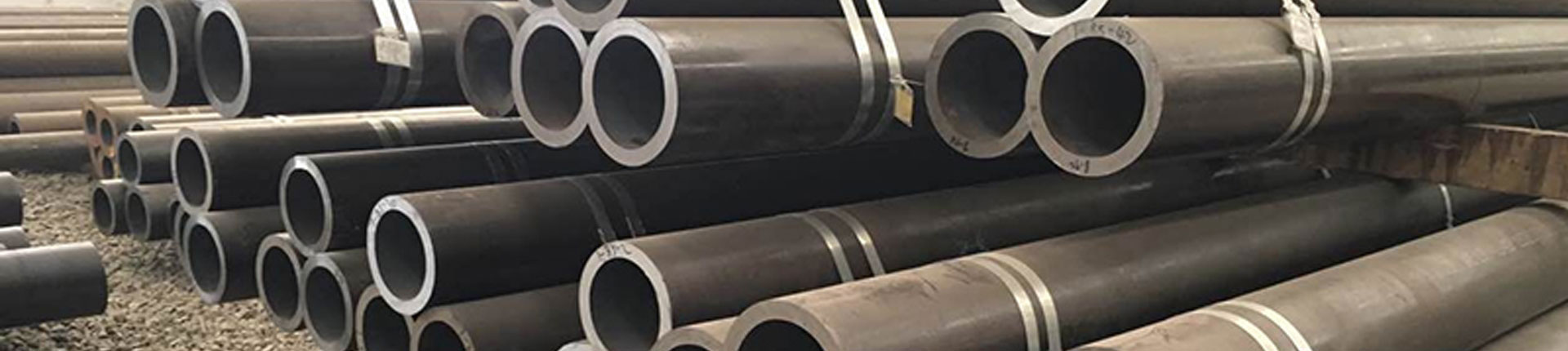

Manufacturing Process

The manufacturing process of ASTM A572 steel pipe consists of the following key steps, which will be explained below according to a clear structure:

Raw Material Preparation:

Iron is smelted into steel through smelting equipment such as electric arc furnaces or blast furnaces. This step is the basis for ensuring that the pipe has the required chemical composition.

Continuous casting:

The steel obtained from smelting is poured into a continuous casting machine to produce steel slabs through the continuous casting process. Continuous casting is an important step in modern steel production, which improves productivity and product quality.

Rolling:

The steel plate billet will be sent to the rolling mill for rolling, through the hot rolling, control rolling and other processes to produce the required specifications of the steel pipe.A572Gr65 steel plate is required to be delivered in hot rolled or control rolled condition to ensure that it has good low temperature impact toughness.

During the rolling process, a strict two-stage controlled rolling process is used. Rough rolling stage using high temperature fast rolling, large underpressure to ensure that the rolling penetration and grain refinement; finishing stage control of the opening temperature and final rolling temperature, in order to reduce the impact of mixed crystals on the performance of the steel pipe.

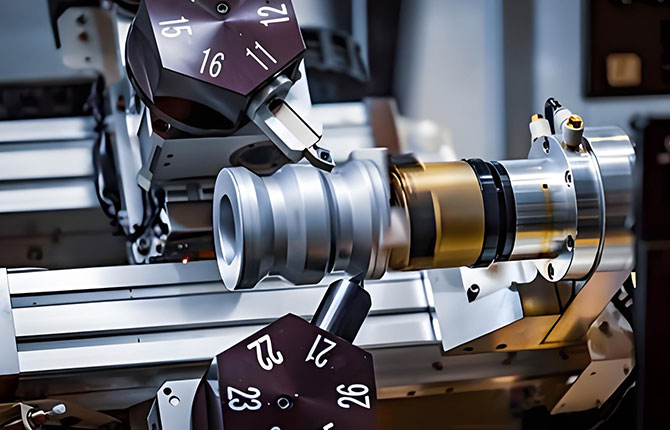

Heat treatment:

Heat treatment of steel pipe after rolling, including normalizing, tempering, quenching and other processes. These treatment processes can further improve the mechanical properties and processing performance of steel pipe.

Quality control:

Strict quality control is carried out during the whole manufacturing process, including chemical composition analysis, mechanical properties testing, surface quality inspection and so on. Ensure that ASTM A572 steel pipe meets the relevant standards and customer requirements.

Special processing (optional):

According to customers' requirements, the steel pipe is subjected to special surface processing, such as hot-dip galvanizing anodic oxidation, environmentally friendly spraying and so on. These processes can improve the corrosion resistance, aesthetics and service life of the steel pipe.

Finished product inspection:

Conduct finished product inspection on the completed ASTM A572 steel pipe, including dimensional measurement, appearance inspection, non-destructive testing and so on. Ensure the quality of the steel pipe meets the relevant standards and customer requirements.