Tianjin Yuantai Derun Galvanized Square Tube Spot Processing

Tianjin Yuantai Derun offers galvanized square pipe spot processing services

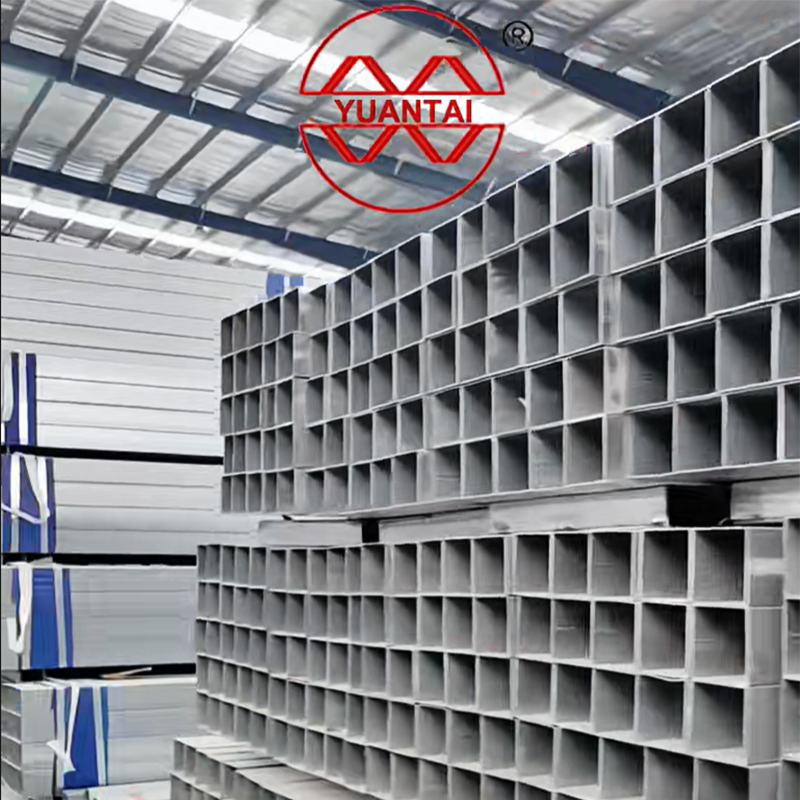

Tianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd., a large-scale square and rectangular pipe production base in North China, provides comprehensive galvanized square pipe spot processing services, covering the entire process from spot inventory, custom processing, and quality assurance. The following is a detailed analysis of its services:

1. In-Stock Inventory and Specification Advantages

Extensive Inventory, Comprehensive Specifications

Inventory: Over 200,000 tons of black square and rectangular tubing, hot-dip galvanized square and rectangular tubing, zinc-aluminum-magnesium square tubing, and other products are always in stock, meeting large-scale procurement needs.

Specification Range: Supports square tubing sizes from 20×20mm to 1000×1000mm, with wall thicknesses from 0.5mm to 50mm, and materials ranging from Q195 to Q460, offering nearly 9,000 specifications.

Flexible Customization: Custom-to-length production is available, with a minimum guaranteed length accuracy of ±2mm, meeting individual project requirements.

Diverse Galvanizing Options

Blowing Process: Average zinc coating of 30μm (426g on both sides), suitable for general corrosion protection applications.

Rack Plating: Average zinc coating of 60μm, with a maximum guaranteed coating of 100μm, offering excellent corrosion resistance and suitable for harsh environments.

II. Processing Capabilities and Technical Strength

Full-Chain Processing Services

Cutting/Drilling: Precision cutting, supporting special-shaped holes to meet pipe connection requirements.

Bending/Welding: Equipped with cold-bending steel units, we can achieve complex bending shapes. Professional welding services are provided to ensure structural strength.

Customized Galvanizing: We adjust the galvanizing thickness based on the operating environment, balancing cost and corrosion resistance.

Advanced Equipment Ensures Precision

Production Lines: We have 10 hot-dip galvanizing lines and a 600x600 large-section square and rectangular pipe production line, with a daily output of 5,000 tons.

Processing Equipment: Equipped with bending, straightening, and cutting equipment, we ensure processing accuracy and efficiency, with a particular focus on processing large-diameter, thick-walled square and rectangular pipes.

III. Quality Assurance and Testing Standards

Strict Quality Control of the Galvanized Coating

Uniformity Test: No red metallic copper deposits were observed after five consecutive immersions in a copper sulfate solution, confirming no missing coatings.

Adhesion Verification: After a cold bend test (90° bending angle, radius 8 times the pipe diameter), the coating showed no peeling or cracking.

High-Standard Testing

National Standards: Strictly adhere to GB/T6728-2017, "Cold-Formed Hollow Steel Sections for Structural Use," to ensure product compliance.

Company Standards: Implementation of Group Standard T/CSCS TC02-04-2018. Galvanized coating thickness and uniformity exceed national standards.

Certification System: ISO9001 certified. Our products are widely used in construction, machinery, power generation, and other fields, and have an excellent reputation.

IV. Pricing and Delivery Advantages

Transparent pricing, high cost-performance

Galvanized square tube price: Taking the 50×50×3.5mm specification as an example, the ex-factory price is approximately RMB 3,910/ton (prices fluctuate with market conditions, please contact us for details).

Bulk discounts: We support small orders (minimum 1 ton) and large orders, with discounts available for larger quantities.

Fast delivery, expedited service available

Standard orders: Leveraging our extensive inventory and efficient production lines, we offer short delivery cycles to meet urgent needs.

Expedited service: We can negotiate expedited processing to ensure project progress is not impacted.

V. Service Features and After-Sales Guarantee

One-Stop Service Experience

Logistics and Distribution: We handle rail and road transportation, providing door-to-door delivery.

Technical Support: We provide professional support, including construction guidance and quality incident handling, to ensure worry-free customer experience.

After-Sales Guarantee

Quality Assurance: Our products feature a long warranty period and the zinc coating offers excellent corrosion resistance, reducing ongoing maintenance costs.

Prompt Response: Our 24/7 customer service ensures prompt resolution of customer issues and enhances customer satisfaction.