What is the difference between the steel pipes of EN10219 and EN10210?

At present, structural hollow sections are widely used in the construction and manufacturing industries, and different application scenarios require different standards of steel hollow sections. The most common steel pipe standards are EN10219 and EN10210, which specify the quality, performance, and delivery status of steel pipes. Studying their differences is very useful for us.

en10219 vs en 10210

En10219 Definition:

EN10219 is a European standard that provides detailed regulations and requirements for the dimensions, mechanical properties, chemical composition, and other aspects of British standard steel pipes. The EN10219 standard is applicable to non alloy and fine-grained non alloy cold formed welded and seamless steel pipes.

En10210 Definition:

EN10210 is a part of the European standard that specifies the technical delivery conditions for hot-formed welded structural hollow section steel pipes. Specifically, the EN10210 standard covers structural hollow section steel pipes made of non-alloy and fine-grained steel materials for hot forming welding. These steel pipes are commonly used in building structures, bridges, mechanical manufacturing, equipment manufacturing, and other engineering applications.

EN10219 certification and EN10210 certification are European standards for steel pipe products, both of which have high quality standards and are widely used internationally. Both certifications are considered mandatory when manufacturing and selling steel pipe products.

This article aims to introduce the differences between obtaining these two certified products, as well as the benefits of these two standards for the production of steel pipe products and their respective benefits.

EN10219 and EN10210 certifications are important standards for European steel pipe products, ensuring high quality and reliability worldwide. This article emphasizes the differences between these certifications and their respective advantages in steel pipe production.

Although both EN10219 and EN10210 certifications guarantee excellent quality, there are still subtle differences between these two standards.

I. Uses:

EN10219 steel tubes are mainly used in structural applications such as construction, infrastructure development and building frames. While EN10210 steel tubes are widely used for manufacturing hollow sections and have a wide range of applications in mechanical engineering, automotive and other structural projects.

II. Chemical Composition:

EN10219 and EN10210 steel pipes have different chemical compositions, which directly affect their mechanical properties. Compared with EN10210 steel pipe, EN10219 steel pipe usually has lower carbon, sulfur and phosphorus content. However, the exact chemical composition may vary depending on the specific grade and manufacturer.

|

Chemical composition of EN10210-1 European standard (hot formed hollow profiles made of non-alloy structural steel and fine-grained structural steel)

|

||||||

|

Steel Grade

|

Chemical composition limits, % |

|||||

C max | Si max |

Mn max

|

P max |

S max

|

N max

|

|

|

S235JRH

|

0.17 | / |

1.40

|

0.040 |

0.040

|

0.009

|

S275J0H | 0.20 | / | 1.50 | 0.035 | 0.035 | 0.009 |

S275J2H | 0.20 | / | 1.50 | 0.030 | 0.030 | / |

S355J0H | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

S355J2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | / |

S355K2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | / |

Chemical composition of EN10219-1 European standard (Cold formed hollow profiles made of non-alloy structural steel) |

||||||||

Steel Grade |

Type of deoxidation a

|

% by mass, maximum |

||||||

Steel Name | Steel NO | C max | Si max |

Mn max

|

P max |

S max

|

N max

|

|

S235JRH | 1.0039 |

FF

|

0.17 | / |

1.40

|

0.040 |

0.040

|

0.009

|

S275J0H | 1.0149 | FF | 0.20 | / | 1.50 | 0.035 | 0.035 | 0.009 |

S275J2H | 1.0138 | FF | 0.20 | / | 1.50 | 0.030 | 0.030 | / |

S355J0H | 1.0547 | FF | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

S355J2H | 1.0576 | FF | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | / |

S355K2H | 1.0512 | FF | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | / |

a:The deoxidation method is designated as follows:FF: Fully klled steel containing nitrogen binding elements in amounts suffcient to bind available nitrogen (e.g. min. 0,020 % total AI or 0,015 % soluble AI). b:The maximum value for nitrogen does not apply if the chemical composition shows a minimum total AI content of 0,020 % with a minimum AI/N ratio of 2:1, or if suficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. | ||||||||

III. Yield Strength:

Yield strength is the stress at which a material begins to exhibit plastic deformation. Compared to pipes under the EN10210 standard, steel pipes under the EN10219 standard usually do not have significantly higher yield strength. Therefore, it cannot be simply stated that EN10219 pipes have higher yield strength. In practical applications, these two types of pipes may have similar yield strength.

VI.Tensile Strength:

Tensile strength is the maximum stress that a material can withstand before fracture. In general, EN10210 steel pipes usually have high tensile strength, but it is not absolute. In specific cases, EN10219 steel pipes may also have tensile strength similar to or exceeding that of EN10210 steel pipes. When the pipeline needs to withstand higher tensile loads or pressures, the increased tensile strength is beneficial for EN10210 steel pipes.

V. Impact Properties:

The impact performance of steel pipes is crucial, especially in applications at low temperatures and harsh environments. It is generally believed that EN10210 steel pipe has excellent impact toughness, while EN10219 steel pipe may have relatively weak impact performance. However, the specific impact performance depends on factors such as the specific material composition, manufacturing process, and application environment of the steel pipe. Therefore, in industries that require high brittle fracture resistance, EN10210 steel pipes are often chosen. However, in specific circumstances, impact performance testing may be required to confirm whether the steel pipe meets the requirements.

VI. Other key points:

a. Manufacturing process:

EN10219 and EN10210 steel pipe can be manufactured using either hot forming or cold forming methods, depending on the actual requirements.

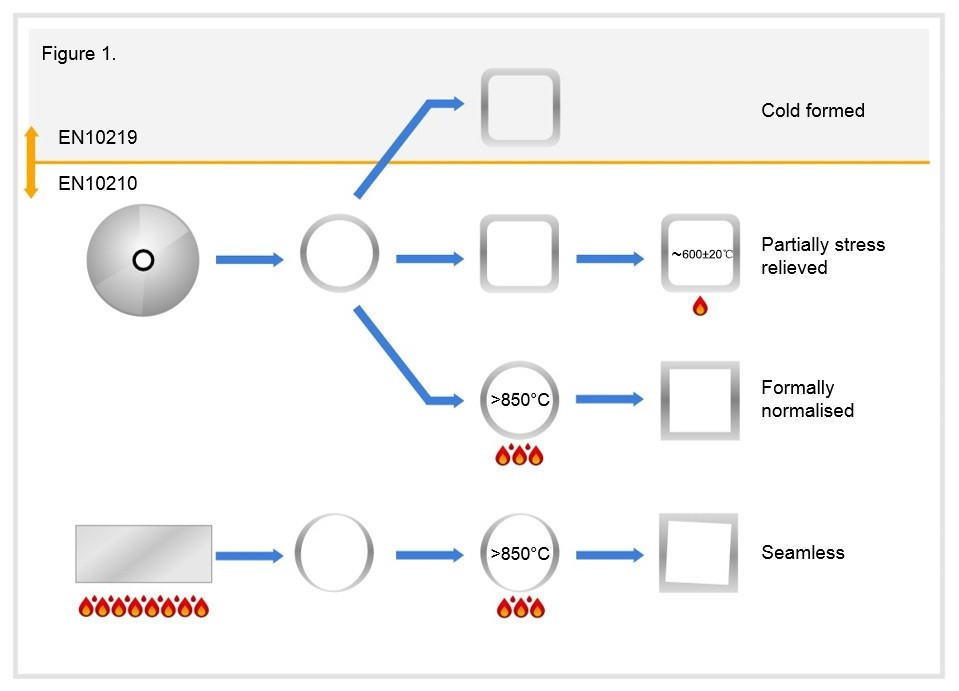

From the picture in Figure 1, we can clearly see that the production process of EN10219 cold formed steel hollow section is much more simple than EN10210 hot formed steel hollow section. Yes, in some more demanding construction projects, the products usually supplied are EN10210 standard steel hollow sections. Instead of choosing EN10219 cold formed steel hollow sections. Among the thousands of projects supplied by Yuantai Derun, EN10210 steel pipe products are more trusted and favored by suppliers.

In this picture,there are 3 lines: Partially stress relieved, Fully normalised,Seamless.

The figure also shows the relationship between these routes and a simple cold formed pipe manufacturing route.

It is generally believed that when producing EN10219 cold formed hollow profiles, a certain amount of stress is retained in the steel during the forming process, which will cause the steel to harden to varying degrees, especially at corners and along welds. This will reduce the ductility of the steel and create weak points in the structure, along which cracks may form.

EN10219 steel pipe(square) manufacturing process

EN10210 steel pipe(square) manufacturing process

EN10210 steel profiles are heat treated to reduce the internal stress of the steel to a certain extent. The temperature and carbon content of the heat treatment are important indicators for determining how much internal stress can be eliminated.

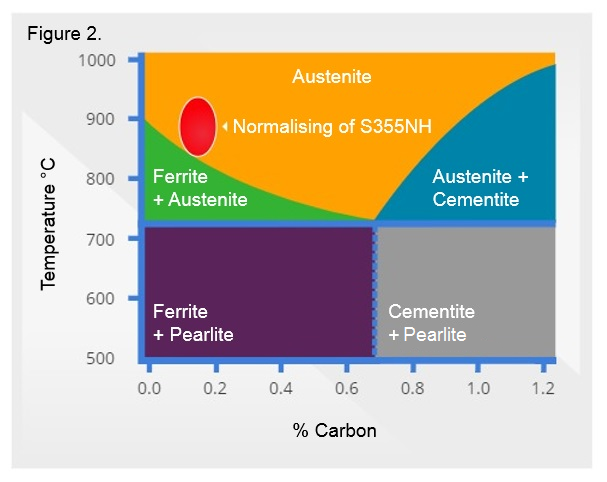

The simplest way to explain the effect of heat treatment is to use a carbon steel phase diagram. This indicates that the internal structure of steel is influenced by temperature and carbon content.

Normally, after placing a cold-formed steel hollow section in a heating furnace for heat treatment, it becomes an EN10210 steel pipe.

The amount of internal stress relief is closely related to temperature. When steel is heated to a lower temperature, it cannot produce new austenite and can only partially eliminate internal stress. When steel is heated to the austenite phase, it is what we call normalizing treatment. During the normalizing process, new austenite particle structures will be formed, and the internal stress reserved during the steel pipe forming process will be eliminated.

For welded steel pipes, internal stress may be one of the defects that cause pipe cracking. So, if people want to reduce the accident rate, they must eliminate the internal stress of the pipeline. By further normalizing processing, hard spots inside the steel pipe can be eliminated, achieving structural uniformity.

Usually, the carbon content of the hollow section of the structure does not exceed 0.22%。From the picture, we can clearly see that steel only enters the austenite phase when the temperature is above 850 ° C. So at this temperature, our hollow cross-section structure can achieve the best normalizing performance.

So, we can summarize the differences between EN10210 and EN10219 as follows:

1. The EN10219 standard is a standard for cold-formed steel hollow sections.

2. EN10210 standard is a standard for hot-formed steel hollow sections. The hot forming treatment also specifies two states of existence in the EN10210 standard.

2.1 One is the normalized state where stress is completely eliminated after normalizing treatment.

2.2 The second type is the state where stress is not completely normalized at lower temperatures. This hollow section will retain some residual stress, especially around the weld seam.

These two states are allowed in the EN10210 standard.

This is an experimental test result graph, where different colors represent different hardness test results. The specific minimum yield strength of the three hollow sections in the graph is 355 N/mm2. The three hollow sections have the same tensile strength, with the only difference being the production process and forming standards used.

The top image shows that the flat edge hardness of the EN10219 cold formed hollow section is quite uniform, but the weld and corners show areas where greater stress is applied, leaving behind harder and lower toughness steel.

The middle image shows that the EN10210 hot formed hollow section does indeed improve the ductility of the main body of the hollow section after undergoing lower temperature hot forming treatment, but high hardness areas are still retained around the weld and corners, especially around the weld. The actual performance of this residual stress hollow section will not be much better than that of the cold-formed section, as failure will begin in the low ductility region (dark region in the figure).

Finally, after normalizing the EN10210 steel hollow section, the welds and corners of the hollow section show uniform and low hardness, providing the highest ductility and best resistance to damage of the steel.

So, how do we distinguish between partially stress relieved steel pipes and fully normalized steel pipes we obtain? In the EN 10210 standard, steel pipes specified as S355NH must be fully normalized, with "N" representing normalization, while steel pipes specified as S355J2H can represent stress relief, but not fully normalized.

After normalizing, the EN 10210 steel hollow section has no residual stress, making it easier to process such a completely normalized hollow section. Significantly improved dimensional stability. The shape of square or rectangular hollow sections is formed again during the normalizing temperature treatment, and their corner contours are more compact, resulting in optimized performance. In addition to performance improvement, the corner radius of the hollow section has also been increased, and the aesthetics have also been improved. They provide a larger and more uniform welding plane for subsequent processing operations.

In summary, truly hot processed hollow profiles have more advantages than cold formed center profiles. We should be cautious of products that may meet standards but cannot provide a complete reduction in project risks. The specific method is that you can always ensure optimal performance in use by specifying a fully standardized hollow section and using the name S355NH.

Yuantai Derun Four Corner Heating Equipment

Heating Furnace Of Yuantai Derun

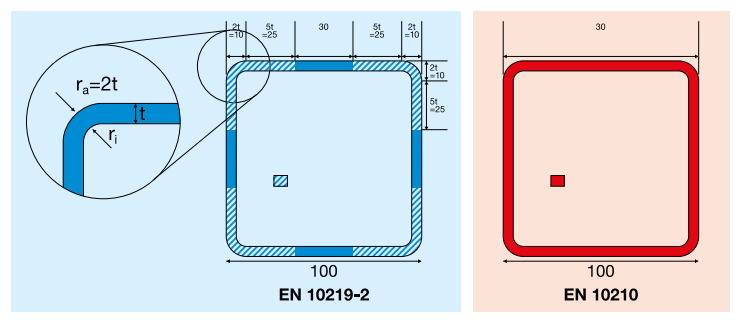

b. Dimensional tolerances:

EN10219 and EN10210 tubes have slightly different dimensional tolerances, which should be taken into account when selecting to ensure suitability for each application.

c. Surface Finish:

From the perspective of surface smoothness, the main difference between EN10210 and EN10219 steel pipes lies in their manufacturing process and processing methods:

EN10219 steel pipe:

Due to the use of cold forming manufacturing technology, the surface smoothness of EN10219 steel pipes is usually high. The cold forming process can produce a relatively smooth surface while ensuring dimensional accuracy.

The characteristics of cold forming make EN10219 steel pipes generally smoother and more uniform in appearance, suitable for applications with high appearance requirements, such as construction and decoration fields.

EN10210 steel pipe:

Due to the use of hot rolling manufacturing process, the surface smoothness of EN10210 steel pipe may be slightly lower than that of EN10219 steel pipe. During the hot rolling process, due to the effects of high temperature and rolling force, some roughness and unevenness may occur on the surface of the pipe.

Although the surface finish of hot-rolled pipes is relatively low, they usually have higher mechanical properties, especially higher strength and toughness, suitable for engineering applications that require higher mechanical properties of pipes, such as bridges and mechanical manufacturing.

Therefore, the selection of suitable steel pipes depends on the specific application requirements. If there is a high requirement for surface smoothness, EN10219 steel pipe can be considered for selection; If high mechanical performance is required, EN10210 steel pipe can be considered.

d. Welding performance:

When welding and connecting our steel pipes, the performance difference between the heat treated EN10210 steel pipe and the cold formed EN10219 steel pipe also needs to be mentioned.

Joint welding is a routine operation during the construction of metal structures. The use of hot formed EN10210 steel hollow sections will make this operation easier, such as a larger welding surface area, including corners, which has good welding performance, making the structure more reliable and stable, and achieving better mechanical effects.

In addition, the brittleness of cold-formed steel hollow sections is not very suitable for certain important requirements of strict building and mechanical structures. This is also mentioned in some specifications and explicitly states that welding is not recommended in the surface area of the product, especially at the corners. (From: Eurocode 3 (EN1993-1-8))

In the figure, we can clearly see that there are many restrictions on the welding area of the cold formed EN10219, especially at the corners. However, the 100% welding area of EN10210 hot formed square steel pipes is not restricted.

VII. China en10210 factory en10219 manufacturers:

There are not many manufacturers or factories worldwide that can simultaneously produce steel pipes that meet the EN10219 and EN10210 standards, and Yuantai Derun is one of them. As one of the leading steel pipe manufacturers, Yuantai Derun is committed to producing high-quality, reliable, and stable steel pipe products to meet the needs of global customers. We have advanced production equipment and technology, strictly following the requirements of EN10219 and EN10210 standards to ensure that the steel pipes we produce meet international standards and have excellent performance.

In addition to Yuantai Derun, there are also other steel pipe manufacturers in China that produce EN10210 and EN10219, such as TPCO. These manufacturers also uphold the same commitment and are committed to producing high-quality steel pipe products to meet the needs of customers.

If you are a global steel pipe purchaser, please feel free to contact us at any time. We will wholeheartedly provide you with consulting services and high-quality steel pipe products.

Conclusion:

EN10219 and EN10210 steel tubes have different uses in various industrial applications. Understanding their differences in terms of use, chemical composition, yield strength, tensile strength, impact properties and other key points is essential to selecting the right steel tube for a particular project or application. Whether it's for structural framing, hollow sections or other engineered uses, an in-depth understanding of these differences will ensure optimal performance and reliability of your chosen steel pipe. If you have any questions about steel tubes in either standard, please do not hesitate to ask one of our account managers.