Manufacturing Process

1. Preparation of raw materials:

The manufacturing of ASTM A500 Tube begins with selecting suitable raw materials, usually high-quality carbon steel.

The raw materials need to undergo strict chemical composition and physical performance testing to ensure that they meet the requirements of ASTM A500 standard.

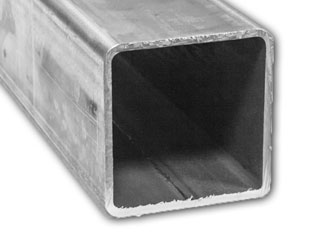

2. Forming:

After cutting and pre-treatment, the raw materials enter the forming stage.

By cold forming processes such as rolling, stamping, etc., raw materials are processed into round, square, rectangular or special shaped pipe blanks as required.

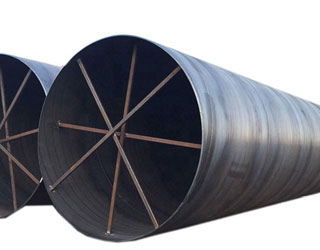

3. Welding or seamless manufacturing:

According to the order requirements, choose welding or seamless manufacturing methods.

For welded pipes, use appropriate welding techniques (such as high-frequency resistance welding, submerged arc welding, etc.) to weld the two sides or edges of the pipe blank together.

For seamless pipes, seamless structures are directly formed through processes such as perforation, hot rolling, and cold rolling.

4. Heat treatment:

For D-grade ASTM A500 tubes, heat treatment is required to improve their mechanical properties and toughness.

Heat treatment typically involves heating to a specific temperature, then holding for a period of time, and finally cooling at an appropriate rate.

5. Dimensional inspection and repair:

The manufactured pipes need to undergo precise dimensional inspection to ensure that their outer diameter, wall thickness, length, etc. meet the requirements of ASTM A500 standard.

If necessary, adjustments will also be made, such as cutting, polishing, etc., to remove burrs, defects, or adjust dimensions.

6. Surface treatment:

According to the order requirements, perform surface treatment on the pipes, such as rust removal, painting, galvanizing, etc.

These treatments aim to improve the corrosion resistance and appearance quality of pipes.

7. Testing and Verification:

Conduct various mechanical and chemical performance tests on the pipes to ensure they meet the requirements of ASTM A500 standard.

These tests may include tensile testing, impact testing, hardness testing, chemical composition analysis, etc.

8. Marking and packaging:

According to the requirements of ASTM A500 standard, mark the pipes, including material grade, size, production date, and other information.

Use appropriate packaging materials and methods to package the pipes to ensure they are not damaged during transportation and storage.

9. Quality control and shipment:

Implement strict quality control measures during the manufacturing process to ensure that each batch of pipes meets the requirements of ASTM A500 standard.