en 10219 hollow section detail

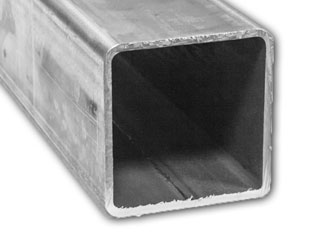

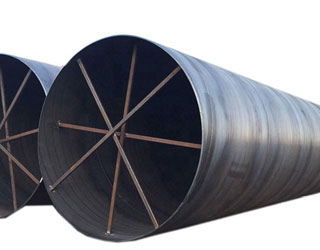

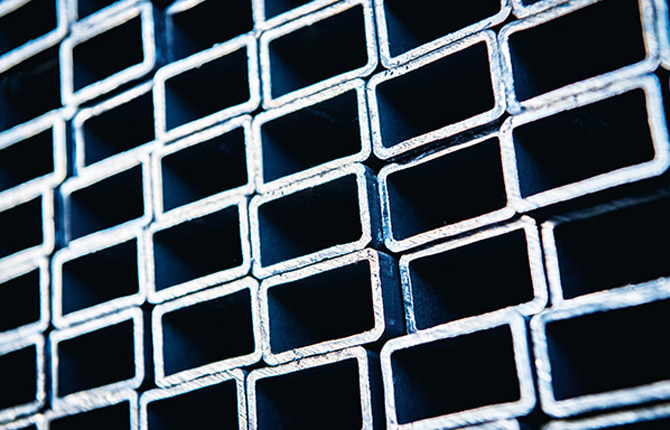

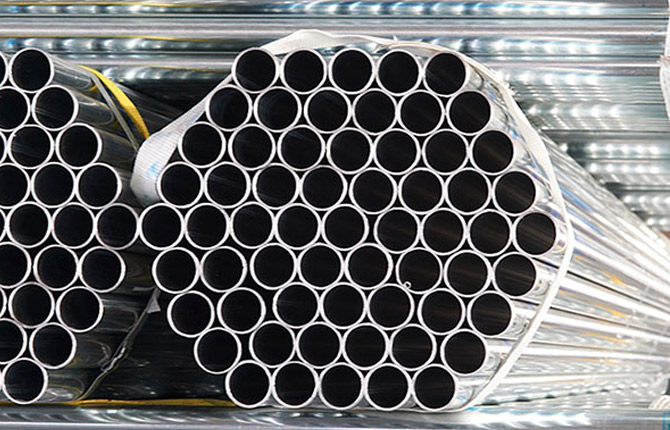

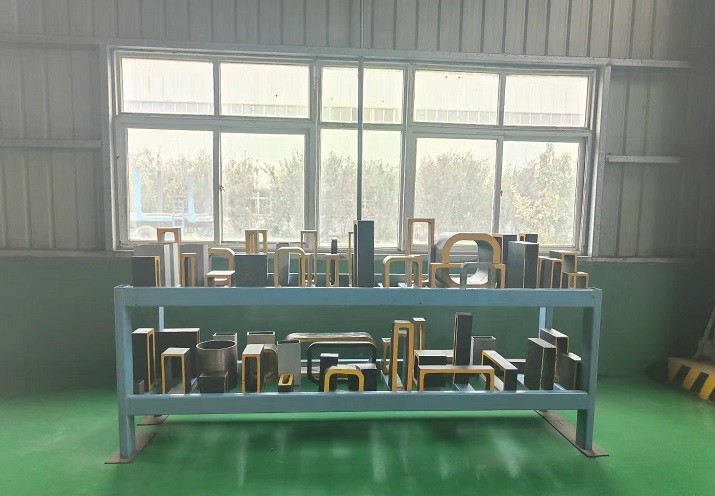

Shape:round square rectangular shaped

Dimensions: Customizable

Square:10*10-1200*1200mm

Rectangular:10*15-800*1200mm

Circular:10.3-2000mm

W.T.: 0.5-60mm

Length:0.5-24m or custmized

Grade:Gr.A,Gr.B,Gr.C,S235/275/355/420/460,,ss400,stkr400/490,Q195/235/355,etc

Standard:En 10219

Surface Treatment:Bare,oil,painted,galvanized,etc.

MOQ:2-5 Tons

Capacity: 5 million tons / year

Packaging:PVC package or follow your needs

Port of origin:Tianjin Port

Payment:TT/LC,etc