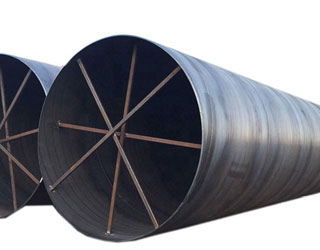

ASTM A53 is a specification for pipe, steel, black and hot-dipped, zinc-coated, welded and seamless. It is intended for pressure and mechanical applications and is also acceptable for ordinary uses in steam, water, gas, and air lines. The specification covers the standard requirements for the physical, mechanical, and chemical properties of the steel grades.

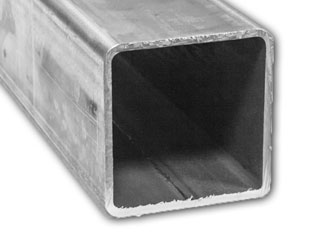

ASTM A53 pipe comes in three types (F, E, S) and two grades (A, B). The types refer to the manufacturing method:

Type F: Furnace-butt welded (continuous welded pipe manufactured with a longitudinal weld joint)

Type E: Electric-resistance welded (ERW)

Type S: Seamless (drawn over mandrel or extruded)

The grades refer to the chemical composition and mechanical properties:

Grade A: Minimum tensile strength of 33,000 psi (228 MPa) and yield strength of 20,000 psi (138 MPa)

Grade B: Minimum tensile strength of 41,500 psi (287 MPa) and yield strength of 24,000 psi (165 MPa)

ASTM A53 pipe is commonly used in applications such as oil and gas transmission, water distribution, structural components, and mechanical parts. The standard is widely recognized and accepted by industry worldwide for its consistency, quality, and reliability.

ASTM A53 pipes are usually made of carbon steel and are available in various sizes, wall thicknesses, and lengths. They are often coated with zinc to provide corrosion resistance, especially in outdoor or wet environments.