Astm a500 stand for a kind of steel standard.It is a standard for the use of steel pipes or steel in the United States.astm a500 grade b stand for a kind of steel grade.

A500 Grade B

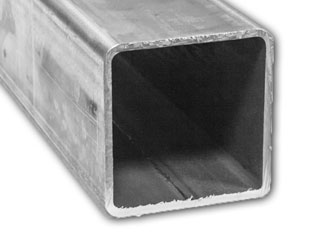

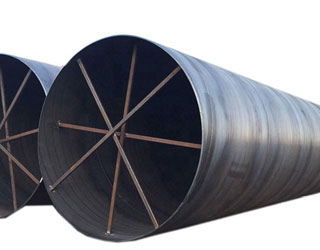

A500 This specification covers cold formed welded and seamless carbon steel round, square, rectangular, or special shape structural tubing for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes.

The minimum wall thickness at any point of measurement on the tubing shall be not more than 10% less than the specified wall thickness. The maximum wall thickness, excluding the weld seam of welded tubing, shall be not more than 10% greater than the specified wall thickness. For square and rectangular tubing, the wall thickness requirements shall apply only to the centers of the flats

Round Structural Tubing – The outside diameter shall not vary more than +/-0.5%, rounded to the nearest 0.005 inch [0.1 mm], from the specified outside diameter for specified outside diameters 1.900 in. [48 mm] and smaller, and +/-0.75%, rounded to the nearest 0.005 in. [0.1 mm], from the specified diameter for specified diameters 2.00 in. [5 cm] and larger. The outside diameter measurements shall be made at positions at least 2 in. [5 cm] from the ends of the tubing.

Square and Rectangular Structural Tubing – The Outside dimensions, measured across the flats at positions at least 2 in. [5 cm] from the ends of the tubing, shall not vary from the specified outside dimensions by more than the applicable amount shown below, which includes an allowance for convexity of concavity.