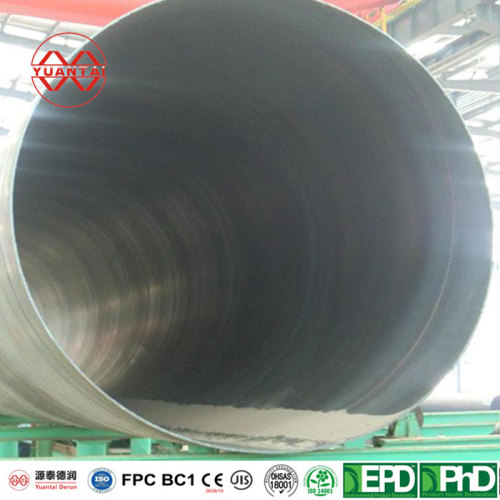

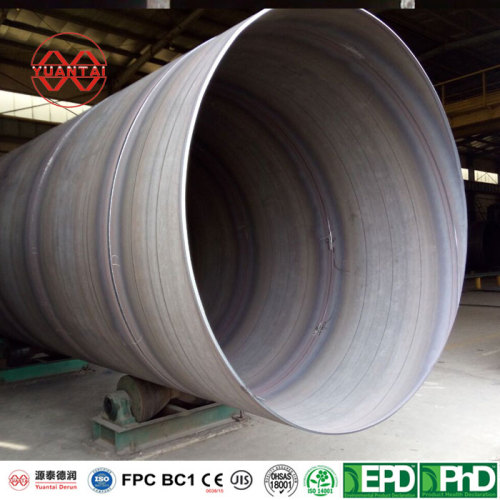

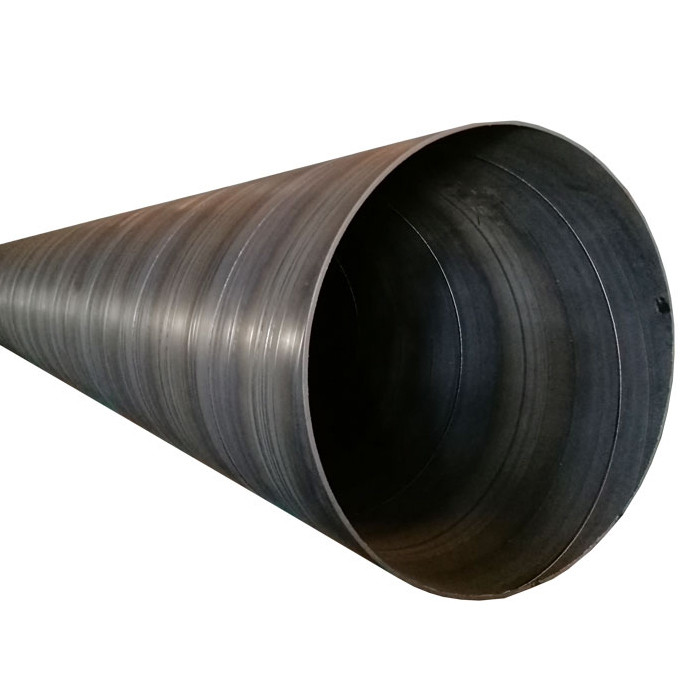

spiral steel pipe

Among numerous structural steel pipes, there is a type of steel pipe with a diameter of up to 3 meters. Do you know what type of steel pipe it is? Perhaps many people have guessed that it is our spiral welded steel pipe. Also known as spiral steel pipes.

Details:

Outer Diameter: 168-3620mm(6.5'-142')

Wall Thickness: 4-30mm(0.15'-1.18')

Length: 0.5-24M(19.69'-944') or cut as your need

Standard: API 5L,GB/T9711,ASTM A252/ASTM A139/ASTM A1097,AWWA C200,SY/T 5037-2000,AS 4041-2006,AS 1579-2001,etc.

Capacity: 500000 Tons per year

Linings: cement lining,polyurethane lining,Epoxy ceramic coating anti-corrosion

Surface coating:polyurethane coating,epoxy coating,galvanized,oiled,painted,bare

Steel grade: Gr.A,Gr.B,Gr.C,S275J0H,S355JR,S355J0H,S355J2H,Q195,

Q235,X42,X52,X60,X65,X70,C250,C350,C450,SS400,etc.

Tolerance: ±5% or follow your requirement

MOQ: 2-5 Tons

Delivery Time: 3-45 days

Brand: Yuantai Derun or OEM

Certificate: API 5L,CE,ISO9001/14001/45001,OHSAS18001

DNV,ABS,BV,EPD,PhD,BC1,EN10210/10219,etc.

Payment Term: TT/LC.

How Is A Spiral Steel Pipe Produce?

(1)Raw materials include steel coils, welding wires, and flux Strict physical and chemical testing must be conducted before investment

(2)The button joint of the strip steel head and tail is carried out using single or double wire submerged arc welding, and automatic submerged arc welding repair welding is used after rolling into steel pipes

(3)Before forming, the strip steel undergoes level, edge cutting, edge planning, surface cleaning, transportation, and pre bonding treatment

(4)The use of an electric contact pressure gauge to control the pressure of the hydraulic cylinders on both sides of the conveyor covers the smooth transportation of the strip steel

(5)Adopting external or internal control controller formatting

(6)The use of a weld gap control device guarantees that the weld gap meets welding requirements, and the pipe diameter, misalignment, and weld gap are strictly controlled

(7)Both internal and external welding are carried out using Lincoln electric welding machines from the United States for single or double wire submitted arc welding, in order to achieve stable welding quality

(8)The completed welds have underground online continuous ultrasonic automatic damage detection, ensuring 100% non-destructive testing coverage of spiral welds If there are defects, automatic alarm and spray marking will be given, and production workers can adjust process parameters at any time to identify defects in a timely manner

(9)Use an air plasma cutting machine to cut steel pipes into individual pieces

(10)After cutting into a single steel pipe, each batch of steel pipes must undergo a strict first inspection system to check the mechanical properties, chemical composition, fusion status of the weld seam, surface quality of the steel pipe, and non-destructive testing to ensure that the pipe manufacturing process is qualified before it can be officially put into production

(11)The parts with continuous sound wave inspection marks on the weld seam underground manual ultrasonic and X-ray re examination If there are internal defects, they are repaired and under construction non destructive testing still until it is confirmed that the defects have been identified

(12)The pipes where the button weld seam of the strip steel and the T-joint intersection with the spiral weld seam are all inspected by X-ray television or photography

(13)Each steel pipe undergoes a hydrostatic test, and the pressure is sealed radially The test pressure and time are strictly controlled by the steel pipe water pressure microcomputer detection device Test parameters are automatically printed and recorded

(14)Mechanical processing of the pipe end guarantees accurate control of the permeability, groove angle, and blind edges of the end face

Specification Table And Weight Per Meter Table For Spiral Welded Steel Pipes

Application

As A Conveying Pipeline

1.Water transportation 2.Agricultural irrigation 3.Natural gas transportation 4.Gas transportation 5.Wastewater discharge 6.Waste gas transportation 7.Chemical product transportation 8.Furnace, boiler, and generator flue 9.Sewer ventilation 10.Dust removal system,etc.

As A Structural Tube

1.Pile driving pipe 2.Bridge structural components 3.Dock support structure 4.Building structure 5.Ocean platform structure 6.Overpass structure 7.Road structure 8.Tunnel structure 9.Dam structure 10.Mechanical equipment,etc.

Water transportation

Foundation pile driving

Agricultural irrigation

Oil transportation

Project

Offshore photovoltaic ground piles

Project Date: April 11, 2024

For more relevant information, please refer to the video:https://youtube.com/shorts/QVAL-zJLdwg?feature=shared

20 products found

ssaw spiral steel pipe (accept oem odm obm)manufacturer yuantaiderun,low cost,high quality,specifications,fast delivery.

China API 5L X52 Spiral Steel Pipe mill Tianjin yuantaiderun,low cost,high quality,specifications,fast delivery.

Categories

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- c channel

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- z channel

- steel profile

loading

subscription

Please send your message to us

Yuantai team has over 21 years of experience in steel pipe project applications, specializing in the production, manufacturing, and customization of square rectangular, and circular steel pipes. Warmly welcome project procurement managers, individual owners, designers, and overall sellers, etc. Write down your requirements and receive professional quotes and technical support.

- Name

- Tel

- *Title

- *Content